Air compressors come in handy for a variety of tasks and supply compressed air to many different tools, both common and specialty tools alike. They are useful in an automotive environment, just about every aspect of carpentry and so many other jobs.

There are tons of different models to choose from nowadays and different metrics like hp, duty cycle, cfm , etc. are key elements you need to understand if you are going to choose the right air compressor to fit your needs.

This is a simplified buying guide I made to give you the essentials on what you need to know about air compressors, hope you like it!

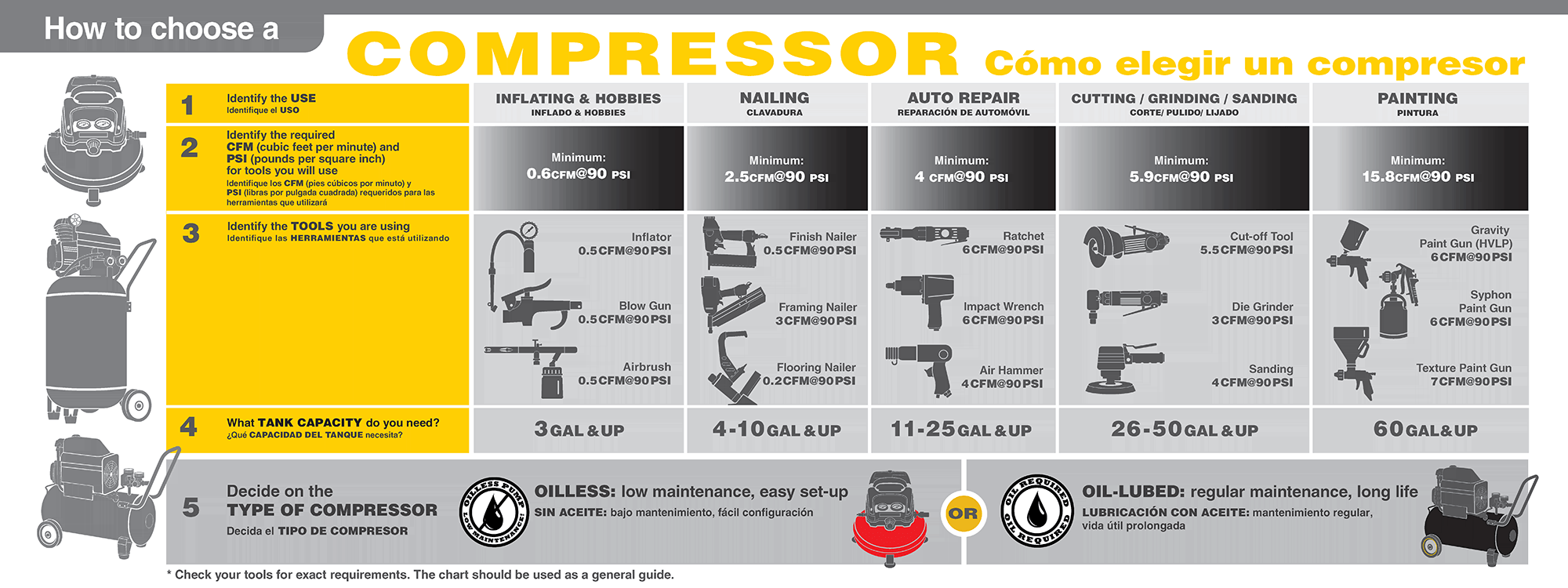

HOW DO I CHOOSE AN AIR COMPRESSOR?

There are so many combinations of shapes, sizes, types, and power sources for air compressors out there, like I mentioned earlier. It’s a better idea to think about your needs first and go from there to narrow down which air compressor configuration will match those needs better.

This should really help to narrow down some of the choices for you and I have provided a few of the most important questions (below) that you should be asking yourself...

- What tools are you going to use most often? - Coming soon!

- Is weight an issue? - Coming soon!

- What's your budget? - Coming soon!

- How often will you be using it? - Coming soon!

AIR COMPRESSORS FOR PERSONAL USE

Personal use compressors are (to me) smaller, more compact units that focus on portability more than anything else and I believe are what MOST people are looking for.

They need to be compact and lightweight so you can quickly fill sports balls, car tires, inflatable pools and the occasional project that needs an air brush or a brad nailer. These will usually have enough power to run most of the popular air tools.

Two good examples of compressor styles that I consider to be "personal use" types of compressors are pancake compressors and hot dog style compressors...

PERSONAL PANCAKE COMPRESSORS

Pancake compressors have a squatted, round air tank with the pump sitting on top of it, a design that has much in common with a propane tank.

They are designed to be easy to lift up and set down anywhere and are designed for lightweight tasks like inflating tires, most nail guns/staplers and powering air brushes.

ridgid.com

Pancake compressors typically come with six-gallon tanks and just enough pressure to operate a brad nailer and other smaller air tools that require smaller cfm ratings. The average price for these pancake style compressors is around the $100 mark and can vary in either direction by roughly $20 or so.

They are affordable, require very little maintenance and ultra-portable – just don’t expect them to run air tools that require more cfm like air ratchets, demo hammers, etc.. They are usually fitted with an electric motor that is more often than not oil-less and does not require any serious maintenance.

PERSONAL HOT DOG COMPRESSORS

Like pancake compressors, they are designed for mobility, low maintenance and ease of use.

Hot dog compressors are so named for the cylindrical tanks that they come with, as these tanks are often short and rounded off at the ends, like a hot dog!

dewalt.com

Hot dog air compressors can hold more air in their tanks depending on the length, with models that can offer up to 12-gallon capacity tanks. They will range in price but for smaller units, you can expect to pay between $100 and $220 for these types and larger, more powerful units can be several hundreds of dollars.

Hot dog air compressors can be horizontal (as shown in the image above) for added stability, or can be tipped up vertically when storing them, which usually takes up less space.

FEATURES TO LOOK FOR:

- Oil-free motors provide maintenance-free conditions making them less of a hassle to store and run.

- Models with low noise levels make them suitable for indoor use even with people around.

- You can find single or dual tank hot dog style compressors in the marketplace but I consider the dual tank models to be geared more towards professional use.

PROFESSIONAL TWIN STACK AIR COMPRESSORS

They are the obvious upgrade to the single-tank hot dog air compressor, and with two bigger tanks, they have not just double the volume, they also have two tanks to push air from.

Twin stack air compressors are so-called for the usual design of two horizontal cylindrical air tanks stacked on top of each other, as you can see from the image on the right..

makita.com

These air compressors are the usual choice for running brad guns and nailers, and they offer a good balance between portability and power. Expect to pay between $200 and $300 for these twin stack compressors.

PROFESSIONAL AIR COMPRESSORS

When the smaller air compressors just don’t cut it, a larger, more professional air compressors are usually for continuous use air tools that require significantly more running time, typical found in larger diy type of projects.

For things like running a brad nail gun to roofing and flooring applications or a larger airbrush, you need an air compressor that can keep up with the steady drain of air and larger, more professional air compressors can put out a lot more cfm, which is exactly what you need.

These compressors still have some features to make them semi-portable, and most come with handles and wheels so you can take them onsite but will usually be a bit heavier than personal use compressors. These are by no means light machines, with some units weighing a good 80 pounds or more.

They are often used in small and medium-sized businesses and see a wide array of uses.

- In automotive body shops for sanding, applying paint and finishing

- On construction sites for roof installation, flooring installation, nail-guns, running pneumatic drills and hammers, and a lot more

- In dental and medical clinics to run equipment where steady, heat-free power it crucial

- In workshops to run air brushes, sand blasters, air blowguns, surface sanders, etc.

- In electronic shops for cleaning machinery

- In auto repair shops for tires, running rachets and pneumatic hammers, and operating lifts and car jacks.

PROFESSIONAL WHEELBARROW AIR COMPRESSORS

Wheelbarrow compressors, like their name, suggests, come with one wheel and two handles and is designed to be moved across rough terrain and job sites, with a bit of effort of course.

They are generally made to be simple, tough and able to power continuous use air tools that require a moderate amount of cfm consumption.

Wheelbarrow air compressors are also meant to be powerful enough to run multiple high-power tools or heavy-duty attachments like impact wrenches and sand blasters. Most models use a gasoline powered motor so gasoline, oil and compressor oil are required to run them.

The wheelbarrow compressors are quite expensive, averaging around $1,000 in price for some of the major brand name models and $500 - $600 for a non-brand name model.

FEATURES TO LOOK FOR:

- They are very portable due to the gasoline engines that power the compressor.

- Cold start valves for gas-powered models help them get going even in cold weather conditions.

- Oil level indicator, drain funnels, and cast-in fill all make it more convenient to do maintenance on oil lube models.

- Roll cage style handles and frame help protect components from damage if you happen to tip your wheelbarrow-type air compressor over while transporting it.

Professional Upright Air Compressors

These air compressors are designed to be installed in place, much like air conditioning units and other semi-permanent pieces of equipment. They can be sealed to eliminate a lot of the noise produced as well.

These are very heavy, usually weighing several hundred pounds but have some of the largest air tanks and the largest, most powerful motors that can produce an insane amount of cfm.

These are great for tools that require massive amounts of air (cfm) and will usually power 98% of the air tools out there.

ONE-STAGE VS. TWO-STAGE AIR COMPRESSORS

Single-stage or one-stage pump compressors compress the air once and are usually found in consumer grade air compressors where energy efficiency is the priority over higher air pressure.

Two-stage air compressors, on the other hand, come with two-stage pumps that compress the air twice. Compressors with these type of pumps are usually those designed to operate more than one set of tools at any one time.

Of course, there is a price difference for compressors that use a two-stage pump because it is usually more efficient and can produce a lot more cfm, in general.

INDUSTRIAL AIR COMPRESSORS

Industrial air compressors are the biggest and most powerful compressors available, and they are often used in large-scale garages and factories. They are designed for continuous use with minimal servicing needed, and they are oftentimes components of even larger machines themselves.

They are used in everything from powering pneumatic machines, running centralized air conditioning and ventilation systems, to operating parts of an assembly line. These machines cost many thousands of dollars (10's of thousands in most cases) and are not often seen by many people outside of the buildings that house them.

INDUSTRIAL ROTARY SCREW AIR COMPRESSORS

Rotary screw air compressor technology is often reserved for units in the 10 kW range and above – you are likely to find these industrial (cabinet-type) air compressors in factories, or similar to those you will find in road construction.

They are often combined with two-stage compressors to deliver even more power, at the cost of more energy input, of course.

HOW DO I COMPARE AIR COMPRESSORS?

Comparing air compressors is pretty straightforward compared to other tools, as there is not much in the way of advanced features for these relatively simple machines.

Mostly, you just need to consider how much air volume and pressure you need to get the job done, then you can also consider a tank size that will give you the operating time you need. That is the BASIC explanation anyways...

Power Sources Available:

Electric Compressors: Compressors that use electric motors are generally quieter, cheaper and free of emissions, if that is a concern compared to their gas powered counterparts.

That’s why most of the smaller air compressors meant for home use are the electrically powered type. These types of air compressors are generally the corded type, although new battery-operated models (cordless) have made their way into the market as well.

Gas Powered Compressors: Gas-powered air compressors are the best fit for job sites that have no immediate access to electricity, or for jobs that require extra power. They are much heavier, require maintenance, and are usually noisier – however, they are also the most flexible type of air compressor.

AIR VOLUME

Air volume is the first standard to use when comparing air compressors, and it is usually measured in cubic feet per minute (CFM), or also Standard CFM (SCFM). This figure, simply put, is the volume of air that the air compressor can output into its tanks in a minute's time.

The tools that require an air compressor to run will typically have a minimum CFM they require for operation. The typical air caulking gun, for example, is best paired with an air compressor that can put out at least 4 CFM.

A bigger tool like a 3/4-inch impact wrench will work with an air compressor that produces around 14 CFM, but they work better with something that can put out 16 CFM or more.

PRESSURE (PSI)

The air pressure that your air compressor can put out is measured in pounds per square inch (PSI). Air compressors that can put out high PSI not only need to have powerful motors, but they also need tough air tanks rated for it as well.

While most car tires will take 30 to 35 PSI, most air-powered tools need something between 90 to 100 PSI to work. For the real heavy duty jobs like operating lifts or running impact wrenches, those will need 200 PSI or more.

Most compressors meet the recommended psi requirements of most air tools and cfm is where the deciding factor usually lies.

CAPACITY

The size of your air compressor’s tank determines the operating time you get out of it – the more capacity you have, the longer you can use your tools before you have to wait for the air compressor to raise the pressure levels to the proper PSI again.

For inflating balls and tires, the usual four to six-gallon tank will suffice. If you spend a lot of time with that sander and airbrush, however, expect to invest in something that has a 60 gallon tank (or more), with the right compressor to match.

MOTOR POWER

Motor power is simply the power rating of the compressor’s electric or gas motor. In smaller units, these are usually stated in terms of horsepower (HP), while industrial units will measure their output in terms of kiloWatts (kW).

In the case of gas-powered units, HP is often given out in terms of running HP and peak HP, as well. Consumer-grade air compressors will usually come with 1.5 HP motors, and 2 HP will usually give you enough power to run most tools.

Cordless models will usually use Volts as a means of powering the compressor and with all cordless tools, the Ah rating of the battery will also affect power and run time.