When looking at all of the different saw blades out there nowadays it can be confusing because there are so many to choose from but some are specifically made for certain materials and work way better than other blades would.

Let’s dive in and take a closer look at what some of these blades are, why they are better for certain materials, what they look like and so on.

Circular Saw Blades For Rough Framing:

Framing blades are probably one of the most popular types of blades out there and some of the most commonly used blades out there, so chances are you will see these in stores more than any other type of blade.

Typically a common “framing” blade will have about 18 - 24 teeth on it or somewhere close to that number. These don’t require that many teeth, just enough to give a pretty decent cut.

A general rule is that the greater the number of teeth on a blade, the cleaner and smoother the cut will be. With rough cut lumber, most of the studs, plates and other wood will be hidden in wall cavities so it will not be visible and does not require a blade with 60, 80 or 120 teeth on it.

Finishing Carpentry Blades:

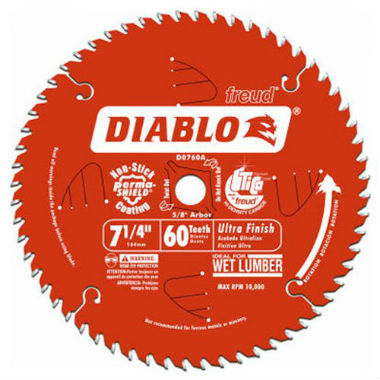

Finishing Blades have a lot more teeth on them compared to framing Blades and are designed to make smoother cuts eliminating chips while cutting the wood and is best suited for finished type materials that will be visible.

Some examples of materials that you would use a finish blade for would-be baseboards, interior crown molding, hardwood flooring and so on which will all be visible and will need to be cleanly cut without damaging the material in the process.

How many teeth a finished type of sob label have is really dependent on the type of material you are cutting, how big of a saw you are using and what manufacturer’s product you are using. Some of these blades can have anywhere from 30 teeth all the way up to 70 teeth or more in some cases.

Circular Saw Blades For Fiber Cement Board:

Saw blades that are made for cutting through cement fiberboard (cement backer board, cement lap siding, etc.) looks very different from any other type of blade and they tend to have a small number of teeth on them.

Most types of cement fiberboard blades have anywhere from 4-10 teeth on them and this reduces the amount of dust that the saw produces and allows for a smooth cut in the process.

It is possible to use a standard framing type of blade to cut these types of materials but it would produce much more dust and last a fraction of the time that a blade specifically designed to cut that type of material would.

Different Metal Cutting Blades:

There are really two different types of blades that can cut through metal and these are abrasive type of blades (smooth look to them) and blades that have teeth on them.

There are different saw blades that are better designed to cut through different types of metal (aluminum, sheet metal, steel, etc.) and these also have different teeth counts on them, like the wood blades have.

Abrasive Type Of Metal Cutting Blades: The abrasive type of blades are the ones that most people are familiar with when cutting metal and they are much more inexpensive than the other types. These tend to give off a lot of sparks during the cutting process and the blade will actually get smaller as you cut with it.

These are made from different abrasive materials (fiberglass) and are pretty common so you can find them for just about any type of saw and they are available in many different sizes.

Metal Blades With Teeth: The other type of blade for metal cutting resembles a wood type of blade but if you look closely, the teeth are flatter and less sharp.

These typically produce less sparks when cutting and are more expensive than the abrasive type of blades but are far superior, in my opinion. They seem to last longer and are less dangerous than using the abrasive types of metal cutting blades.

Circular Saw Blades For Cutting Masonry Materials:

There are only two different categories that these types of blades fall into and these are basically an abrasive type of blade (like the metal ones) and diamond blades (also used for concrete). There are a few differences between the two different types like cost, performance, blade life, etc. Let’s take a look at some of the differences...

Diamond Blades: Diamond blades will last a lot longer than an abrasive one and will last quite a bit longer, not just a little bit. I would safely say that a diamond blade would last 10x longer or more, depending on the quality of the blades themselves.

These are the same types of blades used for concrete as well and the have a flat type of tooth on them (some models) and those teeth are coated with tiny particles of diamond dust which are very hard and will cut through cement, concrete, etc.

Abrasive Blades: These abrasive blades are made from inexpensive materials and are much less expensive than the other type of masonry blades. These are only suited for cement based materials and will not work on concrete because of the larger aggregate (rocks) in the concrete.

Cutting Concrete - What Blades Should I Use?

Cutting Concrete: Cutting concrete will require a special blade (usually a diamond blade of some sort) and there are many different saws that can cut through concrete and the blades will differ slightly in appearance.

circular saw blades Made Specifically for plywood

Circular saw blades for plywood typically have more teeth to them and these can range from 40 teeth all the way up to 100 teeth are more just depending on how find the cut you want and what type of plywood you are using.

A good rule of thumb is that if the plywood is going to be seen then use a blade with anywhere from 40 to 80 teeth on it, so you will have a cleaner and smoother cut.

There is no hard and fast rule on how many teeth a circular saw blade made the cut plywood should have but in general a 40 tooth blade works good most of the time, especially if it is a new blade. For cutting plywood that will get covered up, for example Shir on the exterior of the house that will get covered by a stucco, then a framing blade with 18 to 24 teeth would work just fine because you won't see the plywood/OSB.

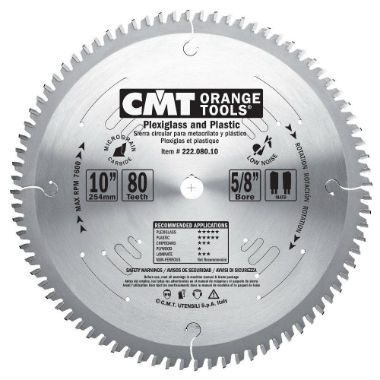

Different circular saw blades for plastics & Plexiglass:

Plastics and plexiglass are pretty similar materials when it comes to cutting them using a circular saw and they have very similar requirements and characteristics so one particular circular saw blade will typically do the job for both types of applications.

Since plastics and plexiglass are a much softer material than wood or metal you will want to use a blade has anywhere from 80 to 140 teeth on it to ensure you get a smooth cut line.

You will want to be sure that the blade is new or in very good condition because plastics and plexiglass tend to melt and if you don't have good teeth on your blade able just heat up and burned through the material creating an ugly and misshaped cut line after you're done.

The image above shows a 10 inch Plexiglass and plastic blade that is typically used on table saws and miter saws so they will not work on a circular saw because of the size but there are tons of circular saw sized blades out there that will cut these types of material.

circular saw blades Made for MDF

MDF is a very dense material and since it is compressed it is very hard on the blades, so if you are cutting a lot of MDF you may want to get a couple of blades, just in case.

Typically, circular saw blades with 60 to 80 teeth work quite well for MDF because they have the ability to cut very sharp, fine lines and are even a good choice for MDF that has laminate on the outside of it.

Dust is something you may want to consider when cutting a lot of MDF because dust tends to where the blades down a lot faster so if you had some type of dust shroud attached year saw or dust extraction system but that year saw that would be not only better for your health but would prolong the blades life as well.