Drill press runout is one of those terms that are used for a number of tools these days but it has a more specific meaning for a drill press...

Did you know that?

I have written the short answer (in the couple of sentences below) for those of you that are in a hurry and just want a "to the point" answer but there are other variables that you should be aware of when it comes to drill press runout...

What Is Drill Press Run-Out?

Runout is basiclly the amount of "wobble" that is found in the drill press (the drill bit specifically) when it is rotating. This is usually measured in 1/1000 of an inch and is oftentimes tested using a dial indicator of some sort.

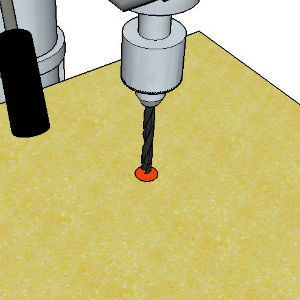

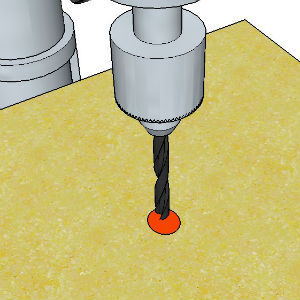

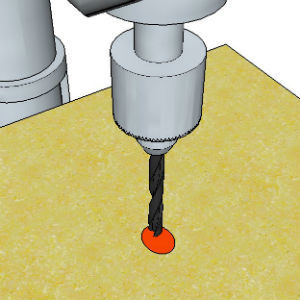

The three pictures (below) show a drill pattern with different variations of run-out (simulated) which will usuall cause the hole to be slightly oblong (egg shape) instead of a circular shape.

No Run-Out

Slight Runout

Excessive Runout

Sometimes the amount of run-out will be so minimal that the naked eye won't even see it and other times (excessive) it will be visible from "a mile away".

Causes Of Drill Press Run-out:

There are many causes that can cause run-out to happen, when it comes to drill presses. The main reasons (typically) are because of the quality of the drill press (including manufacturer's design and defects) and the chuck itself.

Here is a short list of what could cause run-out on a drill press:

- Dirt/debris on the drill bit shaft

- Dirt/debris inside the chuck

- Heat (mainly due to expansion effect)

- Manufacturer defects

- Bent drill bit

- Bent shaft (drill press)

- Drill press bearings

- Damaged part (chuck, shaft, etc.)

Testing The Amount Of Run-out:

A basic test will determine the amount of runout in your drill press and is pretty easy to do with very few tools (just this tool alignment kit)...

- Unplug the drill press. You will not need power for this test and it is much safer to just unplug the machine.

- Install a dial indicator to the drill press table (using a clamp) and make sure that the dial indicator is as close to the chuck as possible. (You may have to readjust your table a couple more times to get this just right.)

- "0" out the dial indicator.

- Spin the chuck on the drill press 2 - 3 full turns to get a more accurate reading.

- Make a note of the reading.

- Lower the table and drop the spindle down all the way. You want to repeat steps 2 - 5 with the spindle all the way down and make a note of the reading on the dial indicator

Measure as close as you can to the chuck itself, in order to get a more accurate measurement. The further down the bit you measure, the less accurate the reading of the drill press run-out will be and will show the run-out of the bit itself, instead.

What To Check If You Have An Excessive Amount Of Run-Out:

There are many different things you can do to check and remedy run-out on a drill press but some of the more common things you will want to look at a bit closer are:

- The Chuck: Pull the chuck and clean the spindle shaft. This is usually the easiest step to take and where most people will tell you to start. You could also just replace the chuck alltogether, if that is something that would make more sense for you.

- The Quill: Adjusting the quill is another way to remove run-out on a drill press and some models have an adjustment dial (or knob) that will do this but it is usually not that effective (in most cases). Replacing the quill is another option too.

- Bearings: The bearings can be checked (in most cases) by lowering the spindle all the way, grabbing the chuck and seeing if there is any back and forth play. There should not be any...

- Spindle: The spindle can be checked by removing the chuck, if it is possible and checking it the same way I described above.

Note: These are just easier and quicker ways to check some of the more common culprits that can cause issues with run out. There are more ways to test which are much more time intense, just fyi.

Things To Consider:

Run-out is usually tested by hand turning the chuck of the drill press and will not simulate the actual run-out of the drill press at operating speeds. So you will get an "educated" guesstimate at how much run-out there is but is not the ultimate test, by any means.

Nearly every tool will have some kind of run-out because all parts (especially moving ones) will have some sort of deflection (naturally). So the truth to this is that no tool will have 0 run-out, brand new and especially over time. The tolerances are very minute though and should be within a standard amount (specified by manufacturer, usually).

Using a straight bit is essentially when measuring run-out on a drill press. If your bit is bent (even slightly) it will give you an incorrect measurement and you will spend a lot more time "figuring things out".

The amount of force applied is also a major contributor to the amount of run-out and should be considered as well. Different materials (wood and metal) will require different amounts of pressure and will have different amounts of run out.