Magnetic drill presses are quite a mystery and not too common nowadays...

Am I right?

They do serve a good purpose though and are more of a specialty tool. The short answer to "what a magnetic drill press" can be found below but there is so much more to these...

What Is A Magnetic Drill Press?

A magnetic drill press is a more portable (smaller) drill press that uses a magnet, usually located at the bottom of the tool and is used to drill holes in steel or a similar type of material. They are used when a standard drill press is not an option.

What Are They Used For?

A magnetic drill press is used when the material is too large to fit into an area or where it would make more sense to have the material drilled "on-site" because of one reason or another.

If you needed to drill a hole in a large piece of I-beam material that weighs several hundred pounds, it would be really hard to try and maneuver that into a shop that had a drill press and get it into exactly the right position. Even if it could be done, a smaller magnetic drill press would just make more sense to use in that particular scenario.

Basics On How To Use A Mag Drill:

Using a magnetic drill press really is not that much different than a standard drill press, you just have to secure it first to the metal material. The process can easily be explained...

- Position the magnetic drill press in close proximity to where you will be drilling the hole(s).

- Wrap a safety chain around the drill press just in case you lose power to the tool and the magnet disengages.

- Install the bit and secure it. Then fill the coolant reservoir with recommended coolant (usually manufacturer recommended).

- Line up the drill bit with the pilot hole or markings on the material.

- Turn on the magnet.

- Turn the "power switch" to the on position.

- Slowly start drilling into the material. Once a "cutting groove" has been established, apply more pressure and maintain that pressure until you have completely drilled through the material.

- Turn the "power switch" off and clean off any chips from the drill bit before proceeding to the next hole.

Here is a quick video that describes the process in it's entirety...

Types Of Magnetic Drill Presses...

Electric: Electric powered magnetic drills are the most common types of models that are used (in general).

They are usually the lightest and most affordable models out there and come in many different sizes. These are usually the most convenient types of magnetic presses to use because you only need a power source (usually 115V) and you're all set!

hougen.com

Pneumatic: Pneumatic magnetic drill presses use compressed air, instead of electrical current, which makes them ideal for cutting environments where water is an issue.

Some pneumatic models can also be used in environments where there may be a flammable or combustible elements or materials but these will need to have the proper ATEX certification.

csunitec.com

Hydraulic: Hydraulic magnetic drill presses are a little bit different than electric or pneumatic presses and are usually used in underwater applications.

They use a "closed loop system" that keeps water from getting into the motor compartment. These are very specific and tend to be the most expensive models but are highly "specialized" presses.

csunitec.com

Cordless: There were only a couple of cordless magnetic drill presses out there, that I was able to find anyways and I assume it's probably because it's a newer item and not every manufacturer has jumped on board yet.

These were quite expensive and the model shown on the right is made by Milwaukee and goes for around $2000! definitely not the cheapest choice and a lot more expensive (nearly double) then some electric magnetic drill presses.

milwaukee.com

Where Can I Find Them?

Magnetic drill presses can be found online at a few different places but if you were to try and find them in a home improvement store, then chances are that they will either not have any in stock (more typical) or a very limited selection as far as manufacturer's, size, and capacity goes.

Amazon: Amazon did have a bunch of electric magnetic drill presses to choose from, in fact it was a pretty surprising amount. If you are interested in getting an electric magnetic drill press yourself, I recommend checking out Amazon just to see what kind of selection they have, you might be surprised as well.

Manufacturer's Websites: Nearly every single manufacturer that makes magnetic drill presses had a website where they listed the different models they make but it was really hard to find a manufacturer that actually sold their tools on their website directly. Most of the time they directed you to another page on their website redefined a list of retailers that sold their products.

Other Retailers: I did find a couple of other retail websites like eBay.com, Northern tool.com and Grainger.com that also sold these drill presses but they were pretty much the same models that Amazon had an were mainly electric ones.

How Much Are They?

There were some variations in price depending on where you left but in general I got a pretty good idea of the overall pricing spectrum for the different types of magnetic drill presses (electric, pneumatic, hydraulic and cordless).

The corded models ranged in price and were anywhere from about $400 in price and ran all the way up to $2000 in price and more in some cases. This price range was basically for the smaller more portable electric models. The larger models that had a higher drilling capacity and were larger in size as well were around $1500 and up.

The pneumatic magnetic drill presses were really hard to find a firm price on and the only thing I was able to find was different manufacturers websites were you could get a quote from them, so it was hard to really compare prices. If this changes I will keep an eye on it and update this page as information comes in.

The hydraulic magnetic drill presses were also pretty hard to find but I did find three or four different models and these were extremely expensive! All three were $3000 and up and these weren't even the larger models that can cut larger holes, these were the smaller models that were able to cut two inch holes (diameter).

Like I stated earlier, there weren't too many cordless magnetic drill presses out there and the majority of them were made by Dewalt, Milwaukee and other top tool manufacturers like that. The few models I did find were pretty competitive in pricing and were around the $2000 mark.

What Kind Of Bits Do They Use?

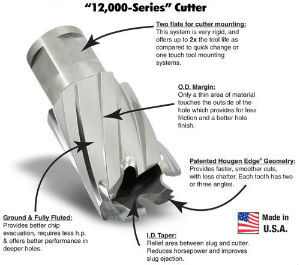

More often than not, an Annular drill bit will be used with a magnetic drill press and looks a lot like a hole saw a bit for wood and cuts the metal the same way that the hole saw bit would (outside only).

The metal shavings run along the outside of the bit and onto the work piece instead of dropping down into the hole.

Annular drill bits come in many different shapes and sizes and are made out of different materials as well and can get pretty customized as far as what types of material they can drill through and what they are specifically made for. For example, some of these annular drill bits are specifically designed to cut through carbon steel, aluminum, stainless steel and even titanium!

It is possible to use a standard drill bit with a lot of these magnetic drill presses but you may need to use an additional accessory (offered by the manufacturer) in order to use these types of bits.

Other Things To Consider Regarding Magnetic Drill Presses:

- The magnet will only adhere to ferrous metals and will not work on all types of metals. An attachment can be used though to attach a magnetic drill press to non-ferrous metals.

- A magnetic drill press can be used in a horizontal position, as well as upside-down if needed. The safety chain is an ABSOLUTE MUST if you are drilling in any position but particularly when using them horizontally or upside-down.

- The magnet used is usually an electromagnet and will only have enough power to hold the drill press if there is a constant power supply going to the tool. If the power was to suddenly shut down (for some reason), then the magnet would no longer work and the tool will fall (if not using a safety chain).