The electric planer, especially the handheld version, is a versatile tool either in the woodworking workshop or out on a construction site. If you are already familiar with a hand plane, then you already have a good grasp of how a handheld electric planer works.

It rides on a smooth metal plate, and in the middle is a rapidly rotating sharp blade the shaves and shapes wood into a smooth, flat finish.

What Are They Used For?

Electric planers are also called power planers, and they are an extremely handy tool for remodeling jobs on the site. Electric planers make short work of uneven joists to straighten them up for drywall.

A wooden door sticks to the jambs? A few passes with a planer will get it opening and closing smoothly. The same goes for window sills that don’t quite close right.

With the proper fence and settings, electric planers can also be used as an on-site jointer to chamfer handrails, smooth the corner of posts and even shape and taper wood trim.

WHICH TYPE OF ELECTRIC PLANER SHOULD I BUY?

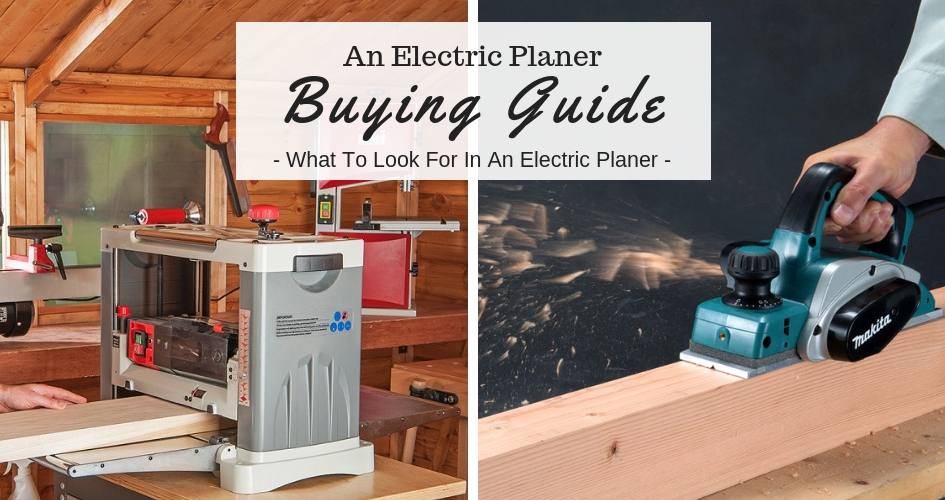

Like most woodworking tools, electric planers come in a variety of sizes made with certain jobs in mind but there are two main types available. The two types are a benchtop type of planer and a handheld electric planer.

Benchtop Planer: These are machines that plane the surface of an entire width of a board and the smaller units (most popular) are pretty compact in size and can usually take off widths of up to 11 1/2" or more, so the width of a 2"x12" which is pretty impressive. You can get these for around $200 - $500 or more.

There are also larger, more industrial type of planers that work just like a benchtop planer but are much larger and are made for much larger dimensions and can handle a lot more volume of wood as well. These will typically range in price greatly but are usually several thousands of dollars and more.

Handheld Electric Planer: Handheld planers are smaller and their blades are usually around 3" wide (max.) and are more ideal for smaller tasks. Planing the 2x side of two dimensional lumber is one area that these handheld planers excel.

These are much more affordable when compared to a benchtop planer too and can range in price from $50 - $200, depending on the type you get.

HANDHELD ELECTRIC PLANERS

For most woodworking tasks in and out of the workshop, handheld electric planers will cover a surprisingly wide array of uses. Whether you are building a deck, adding shelves in a garage, or repairing doors around the house, few power tools are as useful onsite as a power planer when it involves wood.

The business end of a handheld electric planer is a rapidly spinning drum equipped with several blades, called irons. The size of these irons determines the job that you can do with the electric planer – most standard ones come with irons measuring 82 mm wide or roughly 3 1/4".

FEATURES TO LOOK FOR

The number of irons separates the basic models from those designed for pros. Quality planes will come with two or more irons, while basic models will usually come with one.

Sanding cylinders will let you turn your electric planer into a mobile sander, with the proper setting to match.

Suction bags or similar aspiration features collect most ejected chips and shavings into bags. Most sanders will also have attachment points that let you connect the unit to a vacuum cleaner.

Soft grip handles will improve your comfort when using these machines. Electric planers vibrate and chatter a lot, and every bit of comfort helps.

Bench converters or stationary supports lets you use the unit upside down on a bench, turning your electric planer into a mini bench planer or jointer.

Guides or fences are vital if you are to shape the wood into a surface that’s perfectly square with the sides. Not just any fence will do – the longer a fence is, the more accurate your passes will be. Most fences are also adjustable for chamfering or jointing purposes, as well.

Depth scales are crucial to controlling the finish that your planer will impart on the wood. Setting it deeper will cut off more material, while shallower passes are more suitable for a final trim before sanding. Make sure that yours are set in the units that you often use: metric or inches.

Chip direction switches let you choose which side of your planer to eject the chips from (usually left or right). Some models come with chip chutes that can be angled away from your face, instead.

Retractable feet will save your table, as well as your blades if you accidentally put the planer down while the bladed drum is still spinning. Electric brakes work the same way, and both are great safety features to have in your planer.

Tool storage: while most of the adjustments that you will do on your planer can be done with tools from your standard toolbox, planers that come with storage for their own tools built into the unit are just more convenient.

82 mm (3 1/4") planers will let you do most of the household jobs that you will need a planer for. They usually have enough power to shape door edges and add chamfers to the corners of shelves.

For larger jobs, there are bigger planers with shoes measuring 100 mm to 150 mm and more. These electric planers are equipped with more powerful motors to match – they are more powerful, but they are also much heavier and more expensive.

The power of handheld electric planers is measured in amps (A).

HANDHELD ELECTRIC PLANER IRONS: HSS OR CARBIDE?

For electric planers, you have a simple choice to make: High-Speed Steel (HSS) blades, or the stronger Tungsten Carbide blades.

HSS irons are well suited for soft woods like pine. While not as tough as carbide, you can extend the value of your irons if you have a sharpening jig. If you often find yourself dealing with old woodwork with old paint and nails, HSS blades are more easily replaced as well.

Carbide irons, on the other hand, can deal with hardwoods and synthetic woods. They also keep an edge for longer, and most carbide blades are double sided so their use can be extended for quite a bit, too.

Carbide irons do need specialized tools if you want to resharpen them – more often than not, your best option is to just replace them outright. Expect to pay around $20 - $50 for handheld planer blades and around $50 - $200 for tabletop bench planer blades.

HANDHELD ELECTRIC PLANER MODELS: CORDED OR WIRELESS?

Corded handheld planers need to be plugged in, and the cord tends to limit their range. They will never run out of power in the middle of a job, though, plus they are lighter and more powerful compared to battery operated planes of the same size.

For small work that has you moving around a lot, wireless electric planes come in very handy and may be a more suitable choice. Roof installations, repairing decks, or other areas where an outlet might be out of the way or too far away are some of the jobs where a wireless electric planer shines.

The running time of wireless electric planers can be estimated from their Ampere-hour (Ah) rating – the higher the number, the more juice the battery can hold in between charges. You will want a high capacity battery when using cordless models though to sustain the tool for a decent amount of time (minimum 4.0 Ah battery).

BENCHTOP ELECTRIC PLANERS

Unlike handheld electric planers, benchtop planers will rarely see the outside of a workshop. What they lack in portability, they more than make up in size and capacity.

harborfreight.com

While planing a board with a handheld power planer will need a few dozen passes and a bit of skill to make it nice and even, benchtop planers can surface entire boards in one pass.

Pristine lumber that has undergone presurfacing from the mill can be very expensive, depending on the wood. With a quality benchtop planer, you can buy cheaper, rougher cuts and save a few bucks by surfacing them yourself.

These are also great for restoring old wood to new by taking off the top layer in one uniform pass and is where the tabletop planer gets a lot of praise.

FEATURES TO LOOK FOR:

- Depth gauges and stops are crucial in turning rough boards into quality pieces with consistent thickness. It’s almost always better to make multiple passes with shallower bites to prevent tear-outs and damaged edges, and a good gauge helps with that.

- Good dust and chip collection features are even more of a must for the benchtop electric planer. These machines will put out enough sawdust and shavings to make a mess of your workshop from just one board.

- Speed settings allow you to adjust the feed speed for slower, finer cuts or faster, rougher passes.

- Self-indexing knives take out the guesswork when changing irons, which you will be doing regularly especially if you make heavy use of your benchtop planer.

Benchtop electric planers can handle entire boards instead of just joist edges and corners, but these machines are also made with consumer-grade motors and components. Don’t expect them to cleanly cut deeper than 1/8 of an inch at a time, especially if you are feeding them oak or hard maple.

That said, good quality benchtop planers have enough power to do passes 1/16 of an inch deep on softwoods or hardwoods with minimal sanding needed afterward.

Benchtop electric planers are compared in terms of amps (A) and then certain features like number of cutting blades and max rpm are also considered.

HEAVY DUTY ELECTRIC PLANERS

These electric planers are serious heavy-duty machines, the sort that eat full-length hardwood boards for breakfast and ask for seconds.

These units come in tabletop or standalone varieties, and are often made with industrial-grade cast iron sections – chances are you’re not bringing them with you on the jobsite, ever because they typically weigh several hundred pounds.

youtube.com

Unlike handheld and benchtop electric planer models, heavy duty planers come with industrial electric motors that come with their own set of safety features. They are well suited for steady production work or large projects that involve lots and lots of wood.

FEATURES TO LOOK FOR:

- Heavy duty mobile bases add wheels so you can move your electric planer elsewhere in your workshop.

- Add-on shelving systems make it easier to sort and organize lumber so you can just keep feeding them in one after the other on the same platform.

- Magnetic switches let your machine shut itself off in cases of thermal or electrical overloads

- Feed rate settings let you select the feed rate to control the smoothness of the finish

- Solid steel infeed rollers will last for years.

COMPARING ELECTRIC PLANERS

As you consider buying a handheld electric planer, consider your comfort as well before investing in one. Hand planers are noisy machines that you might need to use while you are up on a ladder or on a roof. Get the right-sized tool for the job - look for the size and feature set that best fit your needs.

In general, finish quality is influenced by the number of blades and speed. Higher end models can also handle harder wood types, with a lower risk of burning out or leaving scallops and snipes on the wood.

SIZE: Size for handheld planers are measured in either millimeters (mm) or inches (in.). Basic models come in widths under 3-1/4 in. and are suitable for occasional work. If you use your power tools as part of your job, though, contractor grade planers can come in widths 6-1/8 in. or wider.

For benchtop and heavy-duty electric planers, size is measured in terms of maximum cutting width and cutting height. The bigger units also have a minimum width of board they can take, so make sure to take note of that as well.

NUMBER AND TYPES OF BLADES: Basic models can use one blade, while those geared for carpenters and woodworkers will come equipped with two. Benchtop and heavy-duty electric planers come with three or even more.

Electric planers come with either High-Speed Steel (HSS) or Tungsten Carbide irons, or blades. Carbide blades last longer and are more expensive to replace.

POWER: Electric planers are rated in amps (A) – the higher the rating, the more powerful they are. Heavy duty planers go a bit further than that with motors rated in horsepower (hp).

The maximum cutting depth rating of a benchtop or heavy-duty electric planer is one way to compare overall power and capacity, as well.

For cordless models, battery capacity is rated in Ampere-hours (Ah) – the higher the rating, the longer the battery will usually last. Battery-powered models are also compared in terms of voltage (V) but is usually a less important metric.

SPEED: Cutterhead speed is one way to evaluate electric planers in terms of speed, and this is usually given in Rotations per Minute (RPM). Higher RPM is one way to have more cuts per pass and contributes to a smoother finish.

Feed Rate: For benchtop and heavy-duty models, the feed rate is yet another way to control the number of cuts per pass and is usually given in Feet per Minute (FPM). The lower the FPM, the slower the wood goes through the unit and the more cuts made per pass – again contributing to a smoother finish.