There are a bunch of different metrics for air compressors and some can be very confusing, like CFM...

Wouldn't You Agree?

CFM is a very important metric when looking at an air compressor and is the first thing I (personally) look at when I am in the market for a new one.

There is a lot more than just the meaning of CFM though and you should get "educated" a little bit more on CFM and SCFM, especially if you are going to buy an air compressor, as this is one of the three major deciding factors that SHOULD go into buying one. Let's dive in!

What Does CFM On An Air Compressor Mean?

The short answer is that CFM stands for Cubic Feet per Minute and is a measurement of an air compressor's ability to push out a specific amount of air.

SCFM (Standard Cubic Feet per Minute) is the term more commonly used for air compressors and is essentially the same thing as CFM and is one of the major deciding factors for the overall performance of a compressor.

How Do You Calculate CFM For An Air Compressor?

Calculating CFM (or SCFM) is a pretty simple task and requires some simple math to figure out. These are fun to do when you have your own compressor to see if the "advertised CFM" is what the manufacturer claimed it to be. A special thanks to Jerry for the formula!

This is an 8 step method and goes a little something like:

- The first thing you will want to do is to determine the tank size of your air compressor (in gallons). This is a pretty easy metric defined and can usually be found somewhere on the compressor itself, the box it came in or you can even find it on the manufactures website if you have the model number.

Decimals work best for this math problem so if you had a 4 1/2 gallon tank size on your air compressor go ahead and mark it as 4.5 gallons, instead of the fraction form of the number. - Take the total volume of the compressor's tank and multiply it by .134. The number that you will have (after multiplying) is the total amount of cubic feet in the tank, so you converted gallons into cubic feet.

The .134 represents the number of gallons (US) that are found in one cubic feet of space. - Drain ALL of the air from the tank or tanks on your compressor and make sure that they are fully drained. The best thing to do is to open the valve (usually located at the bottom of the tank somewhere) one - two full turns, to ensure that is open all the way and let it drain out.

Note: Make sure there are no hoses connected to the compressor for this test, you want just the compressor and nothing attached to it.

If you are using a portable compressor pick it up in lightly shaken around to make sure you got all of the air out of the tank. You will also want to pull the pressure relief valve located next to the gauges to make sure you get any remaining air out of compressor (if there's any left). - The next step involves recording the amount of time it takes to fill the tank, so you will need a stopwatch of some sort (your phone will work) and a pen and paper to take notes.

You will be making a note of how long it takes to fill up the compressor with air from the moment you turn it on. You Will want to keep an eye on the tanks pressure gauge (not the regulated pressure gauge).

I would recommend having the air compressor plugged in and the power switch set to the "off position". You will want to turn the compressor on and start your stopwatch simultaneously because the compressor will immediately kick on once you turn the power on because it will be empty and will need to refill right away.

After the compressor stops running and become silent, stop your stopwatch and make a note of the amount of time it took to fill the compressor. - Keep recording the amount of time it takes to fill the tank completely and then stop the stopwatch when the compressor stops running. It will get quiet all of a sudden since the tank is full and no air needs to be added to the tank.

You should also make a note of the psi that the TANK (not regulated pressure) achieved. This will be the maximum pressure and should still be visible when the compressor "cycles off" - Now we will do some math to figure out the rest of the equation. Take the cubic feet of the tank (we determined in step 2) and multiply that number by the maximum psi (in step 5) of the compressor's tank that you jotted down .

- After you have multiplied the cubic feet of the tank and the maximum psi, you will want to divide that number by the atmospheric pressure of your elevation (14.7 psi @ sealevel).

There is 14.7 (rounded off) psi of pressure at sea level and at an elevation of 8,000 feet, the atmospheric pressure is 10.9 psi (rounded off) so a big difference. There is a helpful chart online that will give you the atmospheric pressure of your elevation.

I assume most testing is done at sea level and those marks or ratings are used when the manufacturer lists the "specs" for the compressor. - Take the final answer you got from step 7 (cu. feet of tank X max. psi / atmospheric pressure at your altitude) and divide that number by the number of minutes it took to fill the tank.

The equation simplified:

- Tank size (gallons) (X) .134 = The cubic feet of your compressor's tank.

- Cubic feet of the tank (X) maximum psi that tank pressure reached divided by atmospheric pressure of your altitude

- Take the answer (above step) and divide it by the amount of time it took to fill the tank.

Let me give you an example using the compressor from the youtube video (shown above) to make the whole process a lot simpler and way easier to do...

- 60 gallon tank X .134 = 8.04 cubic feet (tank)

- 8.04 X 160 = 1286.4 / 13.9 = 92.54

- 92.54 / 9.5 = 9.74 cfm @ 160 psi

The above example is a basic equation and fittings used, the age and wear of the compressor, hoses used, tool requirements, leaks, altitude and other elements will play a factor in overall cfm output of a compressor.

What's The Difference Between SCFM & CFM?

CFM and SCFM are pretty much the same thing (basically) and really the only difference is the term "standard" in SCFM. So "Standard Cubic Feet Per Minute" is really just a term that is using "standard conditions" as a basic measurement for the output of air.

Colder climates, higher altitudes, more powerful tools and air leaks can change the cfm of a compressor so a "standard" has to be set to level the playing field and provide a universal way to measure CFM output. This is done at a specific temperature, at a specific altitude (usually sea level) and with no other issues that will affect performance.

I found a great article online that explains the difference in much greater detail than I did her and has all kinds of equations to go along with it!

How Much CFM Do You Need?

Every air tool out there requires a certain SCFM rating in order for it to run properly and the compressor needs to exceed that rating for the best possible results (usually by 1 SCFM or more is best).

Most air tools will also have a SCFM rating @ XX psi, which is the IDEAL pressure that the tool will operate at and the standard is usually 90 psi for most tools but is lower for others, like a hvlp sprayer, which runs at about 20 - 30 psi (in most cases).

Some air compressors come with two different air fittings and if you are going to use both fittings (at the same time) then the compressor must be rated for the COMBINED SCFM requirements of both tools. Compressors that have a high SCFM rating are typically more expensive models that range in price for $700 - 1,200 in price and have much higher SCFM ratings than compressors that are under the $300 mark (which are good basic and more popular models).

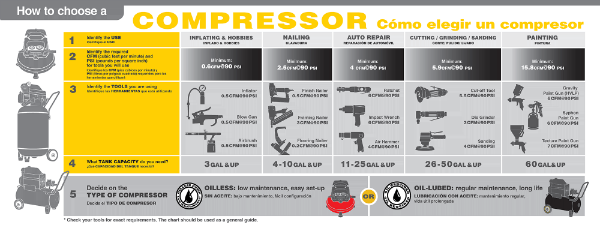

harborfreight.com

The above image is a basic image that shows some of the most common tools used nowadays and the SCFM ratings associated with them. There is another (more comprehensive) list I found online that has a lot more examples and recommended SCFM ratings that I recommend checking out, if you want more information.