Power tools have made huge advances over the decades, and there’s no better evidence than that than the impact driver. It’s a handheld wonder that can effortlessly drive even the longest of screws into hardwood, and does it while leaving the heads clean and sharp.

Getting an impact driver means saying goodbye to stripped fastener heads and half-sunk screws. If there’s anything that can be said to be an example of the right tool for the right job, it’s the impact driver.

At first glance, an impact driver looks like a stubbier, shorter drill. It also looks very much like its closely related cousin, the hammer drill. These three tools, however, have their own roles to play in the their own rights...

IMPACT DRIVERS -VS- DRILLS -VS- HAMMER DRILLS

These tools have a lot in common, which is not surprising since they work using the same principle. Each of these three tools is better designed for a specific purpose but all three can do "general tasks" as well.

Understanding what the difference between the three are will give you a much better idea of what impact driver are suited for.

A Drill (Drill Driver): The classic drill, which is often called a drill driver is a tool you are likely familiar with, and for good reason. A good drill is still one of the best "all-around" tools when it comes to drilling holes and driving screws, and it does reasonably well against most materials, especially if you have a higher end model.

homedepot.com

These excel in drilling and are really made for that purpose but can also drive screws as well. This will drive most screws into most materials but harder materials or driving a lot of fasteners in succession will be the downfall of your typical drill driver.

Hammer Drills: Against concrete and stone, however, you are better off with a hammer drill. This handheld combination of drill and jackhammer is designed to drive a bit into concrete and masonry, and it simply has too much impact power to use for other materials.

boschtools.com

Some hammer drills have different functions that you can switch from though that include a drill mode, a hammer drill mode and a driving mode (for driving screws). The hammer drill is very similar to a drill driver but has the extra capacity of impacting as it spins, which is what masonry surfaces require.

Against concrete walls where ordinary drills would burn out, the impact drill will put in hole after hole, all day and is where they really shine.

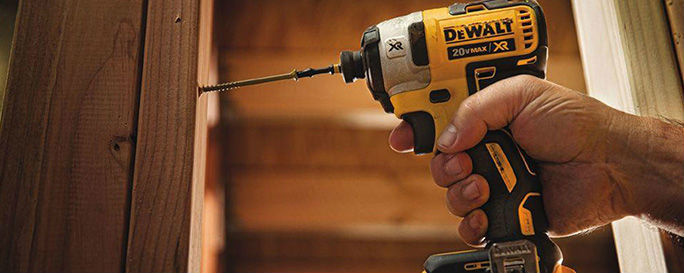

Impact Drivers: When it comes to driving in screws and fasteners, that’s where the impact driver shines and is what sets it apart from the other two choices.

An ordinary drill simply does not have enough torque to reliably drive a screw through hard material, and the high RPM tends to strip screw heads as well. The impact driver, on the other hand, will let you drive 3-inch screws through solid studs with one hand because of the torque of the tool itself.

Impact drivers can save you a ton of time and energy in daily DIY tasks that require driving any type of fastener. Most people tend to never use another drill for driving fasteners after they have used an impact.

CORDLESS AND CORDED IMPACT DRIVERS

When people refer to impact drivers, what they are usually looking for is the cordless, battery-powered variety. A cordless impact driver allows you to be a lot more mobile, which is helpful when you will be moving all over the place. A corded impact driver is more likely to slow the process down and will.

Cordless Impact Drivers: Cordless impact drivers can drive almost any type of fastener you throw at it and having a cordless tool that can handle that task is very convenient. The cordless models are best suited for driving screws into harder materials but can make very light work of the softer materials too.

The cordless models do tend to get hot when you are driving a lot of larger fasteners in rapid succession and heat is the enemy of any tool. You could just allow the tool to sit in between fasteners, switch between two different impact drivers or use a corded model if you have a situation that requires a lot of larger fasteners that need to be secured in a short amount of time.

Cordless impact drivers are rated in terms of volts (V) and the battery rating, measured in Ah is also an important metric.

Corded Impact Drivers: Corded impact drivers do have their place in workshops and garages. For big assembly jobs and projects, consider getting a corded impact driver. Impact drivers are incredibly handy tools that can drive and remove even the most stubborn of fasteners, making them a must-have around a boat, as well.

Corded models also have a much better gear reduction system than cordless models, so they stay a lot cooler and usually tend to last a lot longer than cordless models as well. They are much heavier (in most cases) though.

Corded impact drivers have motors rated in amps (A).

makita.com

WHICH TYPE OF IMPACT DRIVER SHOULD I CHOOSE?

Your choices when it comes to picking an impact driver is rather simple – they do come in one form factor after all, just like electric drills and similar power tools gripped in one hand.

Impact drills only accept one size of hex chucks: the standard 1/4 inch. There’s not a lot in the way of noise reduction features, either, so whichever model you pick make sure to take some safety precautions and put on some hearing protection.

Here is a quick breakdown of the pros and cons of a corded versus a cordless impact driver...

Corded models are cheaper and will be able to handle larger fasteners in rapid succession but are heavier and dragging around the cord can be a hassle for some people.

Corded models are not nearly as popular as cordless models but they still have their place, especially if you have a lot of fasteners to drive. Below is a video on what to expect from a corded impact driver...

Cordless models are quite a bit more money (driver, battery and charger) and require the battery to be charged in order to use them but are a lot more convenient and much lighter to carry around.

12V Cordless Impact Drivers: The 12V impact drivers are a lot smaller and more compact than the 18V models and are better suited for everyday fasteners into soft to mid grade (hardness) materials. These typically don't have the torque to drive larger fasteners into harder materials (one after another).

18V+ Cordless Impact Drivers: The 18V models (and higher voltage models) are a lot more powerful than the 12V models and can drive pretty large fasteners into moderately hard materials. The limits of these 18V+ cordless models will usually involve larger fasteners in rapid succession (one after another) and the heat that is generated from this.

The video below shows the difference between a 12V impact driver and an 18V impact driver driving screws into a couple of 2x4s. This shows a BASIC EXAMPLE of the general power and driving force you can expect between the two drills and how their voltage difference differ.

A Note On Brushless Motors:

If you have the budget for it, always consider impact drivers that utilize a brushless motor. Units with brushless motors are generally more expensive, but if you are using your impact driver all the time, the longer service life will pay off in the long run. Brushless motors run more efficiently, extending the operating time of a cordless impact driver considerably.

Brushless motors also generate less heat, reducing the risk of burn-outs. Most forms of smart electronic features are also available exclusively to brushless models as well. These supporting features let the battery and motor jive together to optimize performance and prevent thermal overload in impact drivers that have them.

Some Basic Features To Be Aware Of When It Comes To Impact Drivers:

- Built-in LED lights illuminate the target area, helping you see and aim even in dark and out of reach places. LED lighting is not only brighter, but it also saves a lot of battery power as well.

- Adjustable Clutches or electronic clutch helps you fine-tune the force the impact driver exerts on the fastener. This feature is very helpful if you are using your impact driver in smaller woodwork like cabinet doors and windows.

- Keyless chucks and fast-release features make changing chuck bits a seamless operation, increasing your productivity.

- Vibration protection helps minimize the amount of vibration the tool gives off but the tool will still vibrate quite a bit, in most cases.

- Special ergonomic designs and features help ease some of the shocks that the impact driver transmits to the hand. Simple things like rubberized pistol grips and a well-balanced design will go a long way towards helping you avoid repetitive stress, especially on jobs where you will be putting in hundreds of fasteners.

- Easy to use toggle switches lets you switch the action from driving to reversing.

- Soft start: instead of bringing on the torque at max RPM as soon as you press the switch, an impact drill with soft start gradually revs up the motor instead. Impact drills with soft start are generally safer to use and will maintain the overall life of the tool as well.

- Neutral switch or switch locks make it so that your impact driver does not drain its battery by preventing accidental switch presses while it’s in your toolbag, for example.

- Brake function makes it so you can stop the chuck spinning right away, which can be very useful for experienced users as they drive fasteners one after the other. Most impact drivers these days have some soft of brake integrated into them.

- Belt hooks are not strictly required, but as with the case of drills that have them, they can be incredibly handy especially if you will be climbing up ladders, scaffolding, etc..

- Charge gauges on cordless models let you know have much fuel you have remaining before you need to plug it in. Some units have gauges on the tool, but it’s generally more convenient to have them on the battery pack instead so you can see the charge status even if it is disconnected from the impact driver.

- A nice carry case, when included with the unit, are always nice to have and keeps everything together.

TORQUE

This is the main metric to measure impact driver by since torque force is the main advantage they have over ordinary drills when it comes to driving fasteners and drilling holes. Torque is measured in inch-pounds, and impact drivers have plenty of it.

- Impact drivers with 12V motors are easily capable of torque in the 750 to 1,200 inch-pound range.

- Those with beefier 18V motors can put out 1,350 to more than 2,000 inch-pounds, enough to drive the thickest of fasteners into some of the hardest materials.

Some manufacturers prefer using feet pounds instead of inch pounds, especially for their bigger models. Corded models with motors rated at more than 9 amps are capable of more than 700 ft-lbs of torque, for example.

Corded impact drivers are usually a lot more powerful than their cordless counterparts.

To compare inch lbs. to foot lbs. just divide the inch lbs. by 12. An impact driver that produces 1,200 in. lbs. of torque is capable of producing 100 ft. lbs. of torque (1,200 divided by 12 = 100 ft. lbs.)

IMPACTS PER MINUTE (IPM)

Since impact drivers are part of the power driving family of power tools, manufacturers will also cite Impacts per Minute (IPM) as a point of comparison. As the name suggests, IPM counts how many blows the internal hammer makes in 60 seconds. The higher the IPM, the faster an impact driver can pulse.

Most models will cite their IPM as “No Load IPM” figures – that is, the IPM they can put out while in the air. Both 12 V and 18 V models typically put out IPMs between the 1,750 to 3,750 IPM range.

A higher IPM generally means that you can drive stubborn fasteners in (or out) faster for the same torque.

ROTATIONS PER MINUTE (RPM)

Modern impact drivers try to save on power by not delivering the absolute maximum Rotations per Minute (RPMs) all at once. That’s why most tools have three or more RPM stages you can engage with ever deeper presses of the trigger. Low RPM ranges generally go to 800 to 850 RPMs, while maximum No Load RPMs can go up to 3000 RPMs or faster.

As you might expect, the higher the RPM, the faster an impact driver can get the job done. It’s not as much as a factor for impact drivers compared to drills and planers, though. In fact, too high of an RPM at the start tends to strip screw heads and ruin soft wood, which is exactly the problem you want to avoid as you select your impact driver.

VOLTAGE OR AMPERAGE

Cordless impact drivers come in: 12 volt, 18 volt, 20 volt, 24 volt versions (possible more) but the most popular sizes for cordless impact drivers are the 18 V versions and the 12V versions.

Corded versions go for anywhere between 7 A to more than 9 A.

BATTERY CAPACITY

For cordless models, battery capacity is measured in Amp hours (Ah). The higher the Ah, the bigger the capacity of the battery, the longer it will last between charges.

The popular power tool brands will usually include battery packs that are interchangeable with their other tools, as well, especially if your impact driver comes in a combo kit with, say, a regular drill and are usually a lot better deal than buying everything individually.