Increasing your table saw's ripping capacity can seem out of the question, when you think about it...

Right?

There are a couple of ways you can actually do this though and they are really a trade-off of time vs cost (for the most part).

In this article, I am going to show you three of the main ways you can increase the rip capacity of your table saw to get a little bit more bang for your buck and to prove that it can be done!

How Do I Increase The Rip Capacity Of My Table Saw?

The short answer would be to either add a larger table to one side of your table saw, readjust the fence sliding rail somehow or to buy an extension table that is specifically made for your table saw.

These are the three main ways you are able to increase your ripping capacity on a table saw.

1. Make A Table To Extend The Overall Ripping Capacity Of Your Saw...

One of the most popular ways of increasing the rip capacity on your table saw would be to build a separate table off the side of the saw (usually the right side) two that you have that additional work space.

This will not only make the table larger but will actually allow you to use the fence as well, if you build it right and have the proper table saw to do so.

PROS

CONS

Most of the tutorials I saw online used a fence system that basically clamps on to the guide rails. The only model that I could see having issues with is any type of Dewalt table saw.

This is because they used their rack and pinion system (for their fences) instead of a sliding fence system. It probably can be done but you have to either try to make an extended rail or swap it out for something else altogether.

A Clamping Fence System:

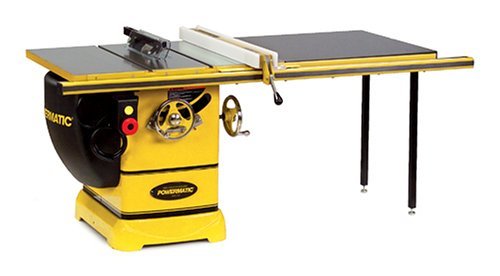

The table saw that use a clamping type of system, like the picture on the right illustrates seems to work the best when deciding to add additional table space to your table saw.

It is much easier to build a fence guide rail like this one as opposed to a rack and pinion type of system (like DeWalt uses) or some other rail system that is more intricate.

For the most part, out of all of the different table saws I came across that use a clamping fence system it would be very easy to replicate the rail out of wood or metal with little to no modification of the material itself.

This is mainly due to the "simplistic shape" of the rail, usually being square or rectangular in shape.

A Rack And Pinion Fence System:

Dewalt's rack and pinion system that they use for their fence comes in pretty handy but may not work that great when you want to extend the size of your table on your table saw.

The picture on the right illustrates why you would run into some typical issues but if you have some time on your hands, some metalworking school's and some patients you could probably make an extended rack that would work with your existing system.

I looked online and didn't find any longer racks offered by Dewalt, so for now the only option would be to either build one yourself (a longer one) or to completely remake how the fence slides on the tool.

You may also want to check out fences on Amazon, to see if there is anything you can use on you particular model and if not, then it will work for a bit of inspiration too.

You should also browse their selection of table saw accessories section, to see if there is anything in there that may work.

Tutorials Online For Making Extending The Table: I found a couple of different tutorials online that describe the process in great detail for the most part but the one problem I did come across was that there is not a tutorial for every model of table saw out there.

So you may have to just watch the video and make modifications to your particular model

Here is a short list of what I found online:

2. You Can Modify Your Existing Fence And/Or Fence Railing To Get A Little More...

Modifying you existing fence and fence rail is another option that people really like because you keep the main functionality of the table saw.

You also don't need to have any extra pieces to carry around with you and you can actually get quite a bit more rip capacity by doing this, for some models anyways.

This is a lot more intricate and will require some disassembly, measurements, modifications and a little bit of ingenuity on your part.

But if you watch a couple of tutorials to get a general overall idea of how people are doing it, you will see that it really isn't all that difficult and really just requires a little bit of planning ahead of time to make the project go smoother and have a successful outcome.

PROS

CONS

The Basics: From the couple of tutorials I found online where people modify their existing rail system on their table saw I found that really the biggest part of the project is extending the rail itself.

Make sure you have enough clearance for your fence to slide (smoothly) and having enough support screws installed.

When doing this you will have to change where the bolts line up and may even have to possibly make new holes.

In addition to that, you'll also have to add an aftermarket type of ruler (which are) if you want to use the stock measurement line.

How It Works: The basic instructions on how this method works is by shifting over your existing fence rail to give you a little bit more ripping capacity.

Nearly every table saw manufacturer out there uses a pretty basic fence system and they all have a maximum ripping capacity to them when the fence and fence rail are extended all the way out.

What most people don't realize is that the fence rail can usually be extended even further than what the manufacturer sets the maximum width at.

This process usually entails:

- Disassembling the fence and rails

- Shifting it over

- Making new holes for screws (if needed)

- Reassembling the fence and rail

- Modifying the measuring indicator (replacement can be found on Amazon)

There is one tutorial that is pretty in-depth on Jay's Custom Creations and it goes into detail about how he did the same thing to his table saw but he is using a Grizzly 0690 table saw.

So it is good as a "general guide" but you may have to make some modifications for your particular model. He also made a video that shows the process (sped up version) that you can find here.

3. Look For Table Extensions For Your Particular Model...

The third option you have would be to buy a table saw stand that has a table extension and a larger rip capacity because users and auxiliary fence instead of the built-in fence that comes with the table saw itself.

PROS

CONS

There are only a select few that are made and only certain models will work for these (usually the larger table saws) so it will be an option for those of you who are using larger contractor/portable table saws.

rousseau.com

The image (above) shows one of these tablesaw stands that I am are wearing to and is a little bit different than the traditional stand you may think of for portable or jobsite table saws.

Notice how the fence that is used replaces the stock fence of the Dewalt table saw, shown in the picture and even their patented rack and pinion fence system can use this to increase the capacity up to 27 inches (for this particular model).

The downside to this is that this particular model, which I found on Amazon will run you nearly $400 so it is not the cheapest option by far.

In fact is the most expensive option but doesn't acquire modifying the table saw in any way, shape or form which is a plus for some people and maybe even a selling point.