Most power tools fall into one of two categories – tools that make it possible for you to do something, or tools that make it faster or safer to do a task that you are already capable of doing.

The reciprocating saw, for most of its applications, definitely fall into the latter category. While the things you can do with a good reciprocating saw will not be much different from what you can already accomplish with a hand saw or even a circular saw, this tool makes it possible to do the same tasks in a small fraction of the time it would usually take.

What Can You Use a Reciprocating Saw For?

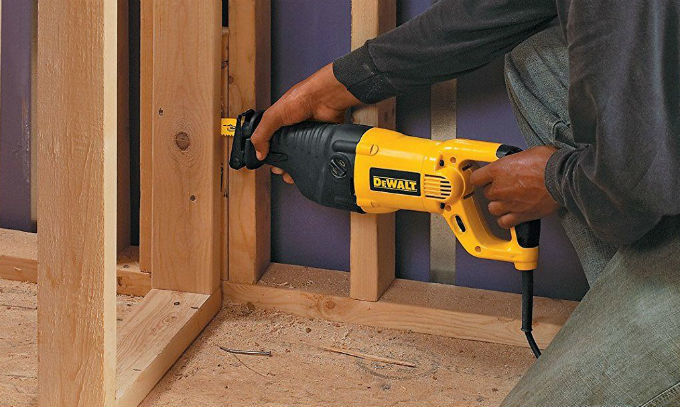

Reciprocating saws are simple power tools that do one job really well – making rough cuts. Good reciprocating saws are tough and are built to take a beating, plus reciprocating saw blades are inexpensive (in comparison). This makes the tool a great all-around aid for renovation and demolition jobs.

Reciprocating saws, with the right saw attachments, can cut through drywall, wood, nails, metal pipes, PVC pipes, trees, and other materials. They are perfect for reaching through tight spaces where other tools simply won’t fit – they are perfect for taking out wall studs, as well as making plunge cuts through drywall.

These tools are also perfect for making quick cuts of copper pipes and PVC pipes that are already installed. If you are using trees for the holidays, a reciprocating saw is also the perfect tool to trim off extra branches cleanly and efficiently.

In the workshop and garage, these are often used to make cuts in plastics, fiberglass, sheet metal, and aluminum to help with automotive body repair, muffler and exhaust work, and sunroof installations.

How Do I Choose The Right Type of Reciprocating Saw?

As far as reciprocating saws go, there is basically only one type to choose from – the handheld reciprocating saw. Most models do not stray far from the two-handed design with the pistol grip, and for the most part, you have two options to choose from: corded or cordless reciprocating saws.

Compact Reciprocating Saws vs. Regular-sized Reciprocating Saws

Compact reciprocating saws are often offered as cordless models, and unlike their regular-sized counterparts, these saws are not really meant for demolition jobs. They are more in demand for their pipe-cutting abilities, and their compact size makes them a popular option for plumbers.

Unlike regular-sized reciprocating saws, compact saws are often made for one-hand operation. Most compact saw kits also come with much shorter blades, as well.

Gardeners and landscapers who often deal with irrigation systems and lots of tubing will also find the compact reciprocating saw very useful for all manner of jobs in the garden, lawn or farm.

Corded vs. Cordless Reciprocating Saws

As far as reliability and power go, corded reciprocating saws are the standard when it comes to these cutting tools. Reliable power provided by a cord means consistent cuts with every press of the trigger, plus the corded reciprocating saw is usually lighter and more balanced than the equivalent cordless reciprocating saw, due to the lack of a heavy battery.

That said, corded reciprocating saws do come with all the limitations that dependence on a power outlet will impose on a power tool. If you are picking up a corded reciprocating saw, make sure you have an extension cord that is rated for the length from the outlet (cord gauge) and amperage of the tool.

Cordless reciprocating saws are much more portable than corded saws and are simply the better choice when it comes to cutting softer materials or when you have a bunch of small cuts to make in different areas.

Modern lithium-ion batteries and brushless motors have also allowed battery operated reciprocating saws to offer almost the same sawing power as corded saws, if for a limited time.

With cordless reciprocating saws, the risk of accidentally sawing through the power cord is also absent. Battery powered reciprocating saws also shine when it comes to jobs that force you to go up ladders to reach tight spots with your tool – with no cord to get in the way, cordless saws offer a huge advantage when it comes to maneuverability and convenience.

With all the portability and convenience that a cordless reciprocating saw provides, there are also the drawbacks when it comes to operating time. Not only is your running time limited, you then have to spend even more time waiting for the battery to charge up if you don’t have a spare one ready and charged to use.

Higher Ah batteries are recommended (4.0 Ah or higher for these tools) but these can be expensive to buy, especially if you are buying 2, 3 or more at one time.

Pneumatic Reciprocating Saws

Pneumatic reciprocating saws, also called air saws, are popular for workshop and garage use for a wide variety of applications. Like all air tools, you will need a suitable air compressor to operate a pneumatic saw. Once you have everything in place, though, you have a heavy-duty tool that easily outstrips many corded and cordless models.

With no motors on the tool, air saws are lightweight and easy to maneuver, aside from the air hose that tethers it to the air compressor.

Features to Look For In Reciprocating Saws:

Adjustable shoes allow your reciprocating saw to cut in various angles and positions, or adjust the depth of cut when making a plunge cut. They also allow you to expose more or less of the blade to make deeper or shallow cuts from different angles, as the shoe stabilizes the saw against the workpiece.

Variable Speed Control is a must-have feature for reciprocating saws. Most variable speed control features are built into the trigger – a light press makes the saw oscillate slowly, while a full press on the trigger drives the tool to maximum speed.

When cutting metal, it’s always advisable to start the tool at a slow speed to start a groove on the metal, and after that, it’s often a good idea to keep it running at a moderate speed to control overheating and keep the blade sharp.Multi-position blade clamps let you use the blade with the teeth facing downwards or upwards. Some models even have four blade clamp positions or more to allow for flush cuts in both directions.

Vibration control features help dampen some of the vibration or ‘chatter’ of the tool, leaving you in full control of the tool as you make the cut. Good vibration control plus a nicely shaped and rubberized set of handles make for a tool that is comfortable to use.

Quick tool-less blade change features let you swap in a new blade without having to open a toolbox. Some reciprocating saw models use a knurled chuck that can be spun to release or secure a blade. Some chucks have spring-loaded blade lock mechanisms as well that will eject the blade when the chuck is twisted. This feature is a good way to remove hot saw attachments without the user needing to touch them.

Brushless Motors make the tool more power efficient, which makes a big difference in the operating time of cordless models. Aside from greater efficiency and durability, brushless motors also allow manufacturers to add electronic monitoring features that optimize tool performance and prevent thermal overload.

Saw kits with blades included let you use the tool right away.

Integrated LED lighting illuminates the target area, letting you see what you are aiming for especially in dark tight spots.

Carrying case protects your reciprocating saw from damage while in transport.

What is Orbital Action, and How Is It Different From Straight Cut?

Reciprocating saws get their name from the motion they impart on the blade – a back and forth movement that, with enough speed and power, lets the tool cut through a wide variety of materials.

Straight cut reciprocating saws are saws that move the blade in two directions only – forwards and backward. They are ideal for making controlled plunge cuts and smoother metal and PVC cuts that require a lot of control.

Some models, however, offer reciprocating saws with an ‘orbital cut’ action. The saw on this tool, instead of just going back and forth, will trace an oval pattern, hence the name ‘orbital’.

With the blade being moved side by side as well as back and forth, the tool can remove more material compared to the straight cut saw. This is a more aggressive cutting action that gives up a bit of precision for faster and rougher cuts.

Some reciprocating saw models can do both, and they have a switch that lets the tool switch between straight action and orbital action.

Comparing Reciprocal Saws

Comparing reciprocal saws often means looking for the one that cuts the fastest, while also getting a durable tool that will last for years.

Power

Like with most corded tools, reciprocating saws are rated in terms of Amperes (A). Cordless models, on the other hand, are rated in terms of voltage (V), while air-powered models are rated in terms of Cubic Feet per Minute (CFM).

When comparing two models with the same power source (corded, cordless, pneumatic, etc.), the higher the figure, the more powerful the motor or air compressor is. This can give you an approximate idea of how much power the saw can potentially output with a blade attached while under load.

Speed and Stroke Length

The standard for comparing reciprocating saws, regardless of power source type, is the speed. With most models providing variable speed, this figure is usually given in terms of maximum Strokes Per Minute, or SPM.

Typical speeds for corded and cordless models are usually in the 3,000 spm range. Heavy-duty models powered by air compressors, meanwhile, can reach some 10,000 spm or even more.

Aside from stroke frequency, the stroke length is another part of the variable for cutting speed. Longer stroke lengths mean more materials cut per pass, and the faster the cutting speed of the tool. Long stroke lengths also mean a tool that vibrates more than a similar tool with shorter stroke lengths.

Orbital action imparts a bit more stroke length to the blade as the tool moves it upwards and downwards as well as forwards and backward. Reciprocating saws with orbital cutting action features cuts through metal, wood, and other materials faster than those that can only do straight cuts.

Types of Reciprocating Saw Blades

Your new reciprocating blade is just paperweight without a blade to go with it. For most purposes, reciprocating saws use two types of blades: metal and wood blades. Taller blades make for straighter cuts, while thicker blades are less likely to snap or kink. Most reciprocating saw blades are made of carbon steel.

Wood Blades have aggressive teeth similar to those in hand saws and are designed to rip through wood and drywall.

Metal Blades have smaller teeth that are more densely packed, making them suitable for cutting through metal pipes

Pruning Blades have alternating sets of fine teeth and bigger, more aggressive teeth, enabling the saw to rip through green tree branches and smaller trunks in no time.

Multi-Material or All-Purpose Blades are ideal for demolition jobs, with their ability to safely cut through wood with nails and other mixed materials. Perfect for taking out wall studs and other nailed timber.

Safety Tips When Operating A Reciprocating Saw

Like with all power tools, safety is the first priority when handling a reciprocating saw.

Pick a saw that feels comfortable in your hand. With reciprocating saws, having good control of the tool is a vital part of using it safely.

Always use the right saw blade for the job, and always check that the tool is powered off and unplugged before changing blades. Note that saw blades can get very hot – wear gloves whenever possible.

Always wear eye protection, especially when cutting metal with a reciprocating saw.

Reciprocating saws are very loud and produce a lot of vibrations as well. Wear hearing protection whenever possible, and take frequent breaks while using the tool.

Always make sure that the wall you are cutting into does not have live electrical wiring or gas lines. Never operate a reciprocating saw in areas with suspended dust, combustible gas or other suspended matter that can be set off with a spark.

Always read the owner’s manual, and exercise proper maintenance of the tool.