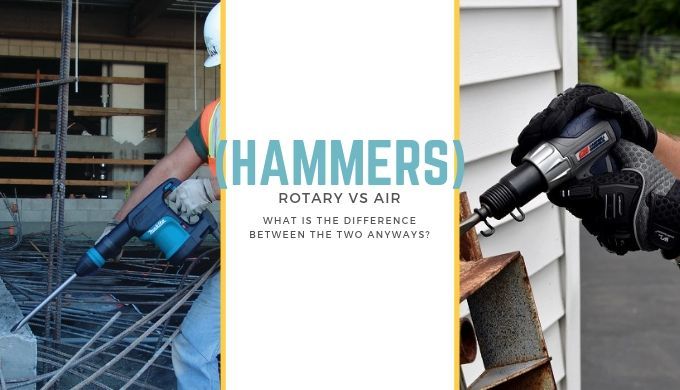

Few people will really have trouble telling apart a rotary hammer vs an air hammer. The former is a hefty power tool, which may be battery powered or corded, and is usually fitted with long heavy duty drill bits that make short work of concrete and masonry.

An air hammer, which is also known as an air chisel, is a much smaller and lighter tool, on the other hand. Air hammers weigh around 3 pounds or so and unlike rotary hammers that are often fitted with drill bits for drilling, an air chisel is usually equipped with any of the wide assortment of tools depending on the task needed at the time.

Just like it says on the label, you will also find an air chisel tethered to the air compressor required to run it. While there are pneumatic versions of the rotary hammer, most workshops and garages will have the electrical kind for their own use.

All those differences aside, both the rotary hammer and the air hammer earn their names from the impact action that they impart on the material they are being used on. Both power tools also make use of a powered oscillating piston, too. Rotary hammers and air hammers direct their impacts parallel to the direction of the tool shaft, and deliver their hammer blows directly to the material itself.

Other power tools with a hammering action will add the impact of a spinning weight to their torque output, in the case of impact drivers and impact wrenches.

Similar tools like the hammer drill use ridged cams to add a minuscule amount of stroke to their drill bits to aid in drilling, too. In contrast, both the rotary hammer and air hammer deliver significant amounts of stroke, and they can do this with the powered pistons they are equipped with.

How A Rotary Hammer Works

A rotary hammer works by combining the turning action on the drive shaft with the impact force delivered by a piston, which is powered by the motor or by compressed air. Rotary hammers do not spin very fast – in terms of RPM, they significantly lag behind fast-spinning tools like drills, hammer drills, and rotary tools. What they lack in speed, they make up in impact power – which works really well on hard, brittle materials like concrete, brick, masonry, and stone.

A rotary hammer, with the right bit, pulverizes the material and uses the spinning flutes of the drill bit to draw out the dust and debris. This makes them ideal for drilling holes in concrete floors, through masonry walls, and other similar applications.

Rotary hammers also have multiple modes you can use – you can run it at “drill and hammer” mode, use a “drill only” setting, or even leave out the spinning motion entirely with a “hammer only” mode. In the latter mode, the tool functions just like an air hammer, which also means that you can use your rotary hammer with a chisel, a digging spade, a scaling tool or any similar attachment you want to use for surface preparation and demolition work.

How An Air Hammer Works

An air hammer works by using the air pressure supplied by a suitable air compressor to operate an oscillating piston, which also drives the tool shaft. Handheld air hammers, or air chisels, are very simple tools that are also easy to operate. Small short barreled air hammers are ideal for light duty tasks, while the longer barreled air hammers are designed for more demanding work if you have the right air compressor to run them.

For most of your metalworking, garage, and woodworking applications, you can run an air hammer with a compressor that can reliably put out 4 CFM. You will be better off, of course, with an air compressor that is capable of much more than that – you not only get more reliable power and air capacity for your air hammer, but you can also run more than one of them if you have to.

What Applications Do You Use a Rotary Hammer For?

Rotary hammers are the best tool for the job if you want to drill into concrete and masonry. Regular power drills and hammer drills may give you a lot of RPM, but they simply do not perform as well on hard materials like mentioned above.

For drilling large, deep holes in concrete slabs, or for making through-holes through a solid concrete or masonry wall, the rotary hammer is your best bet. Despite their slower turning speeds, they offer very fast drilling rates – a feature that you will appreciate when you have a lot of holes to drill.

Machinery installers, electricians, HVAC technicians and other professionals who work with a lot of ground anchors, lag bolts and wall routing will often have their trusty rotary hammer of choice.

By turning the “hammer only” mode on, you can also use the rotary hammer with a chisel or spade attachment to chip off tiles, break off excess pieces of concrete, or even split boulders for your landscaping. The high BPM rates of rotary hammers also make them useful for rough-chiseling walls and similar surface preparation tasks.

What Applications Do You Use an Air Hammer For?

Air hammers, unlike rotary hammers, are used for applications that require precise chiseling. They are small and easy to control, and these characteristics make them ideal for metalworking shops.

With the right chisel attachments, air hammer users can cut sheet metals in a way that does not leave burrs. Air hammers can also be used to shape or flatten metals, which is useful for working with aircraft grade aluminum or for shaping parts out of structural steel.

Air hammers are also the tool of choice for securing solid rivets, which is a common task in metalworking shops that do a lot of bodywork.

In the garage, air chisels give professionals just the right balance between power and control for a wide variety of applications. They can be used to neatly cut exhaust pipes or to give a quick series of taps to free up frozen nuts. They can also be used to safely take apart CV joints, shock absorber fasteners, rubber bushings, and ball joints.

They are commonly referred to as air chisels in woodworking and stoneworking. These tools, combined with the appropriate chisel, can dramatically speed up the chiseling and rough carving phases of stonework and woodcarving projects.

Just like rotary hammers, air hammers can also be equipped with a chisel for surface preparation. An air hammer can be used in this way to scrape off hardened excess mortar, tile, flaked old paint and more.

Rotary Hammer Size and Weight

Rotary hammers are large, hefty tools, which can range from a feet long to a two-handed piece of equipment measuring two feet long depending on the type of bits they are designed for. The smallest rotary hammers, those designed for smaller diameter SDS and SDS Plus bits (not SDS max), will easily exceed a foot long and weigh no less than six pounds.

When you start getting into the SDS Max ranges of rotary hammers, that’s where you will really need two hands to handle your power tool. And when you happen to have one of the older Spline workhorses, it’s like having a mini jackhammer on your hands.

Air Hammer Size and Weight

Air hammers or air chisels are simple, lightweight tools owing to the fact that they don’t have an electric motor inside them, let alone a battery pack. A typical long barreled air hammer will measure just under a foot long and weigh just a little over three pounds. A short barreled model will measure just over 8 inches in length, and it’s just the right size for working inside or under cars and machinery.

The only thing that hampers the portability of an air hammer is the need to bring the air compressor along with you, too, if the job site doesn’t already have one. Most air hammers will have the standard ¼ inch air inlet and will need the right air hose to match.

Rotary Hammer BPM

A Rotary hammer can put out an impressive number of blows per minute – also known as BPM, or the number of impacts that the tool can deliver within one minute.

A typical rotary hammer model can easily put out more than 4,000 BPM, which makes them ideal for quickly pulverizing concrete and masonry. Each impact packs quite a punch, too – you can expect hits of around 2 Joules or more from a decent rotary hammer brand.

Air Hammer BPM

Air hammers also put out a respectable amount of BPM, if less so than the rotary hammer. A heavy duty air hammer from a good brand should be capable of 2,000 blows per minute or more.

What air hammer users value in their tool, however, is the control they have over the hammering rate. Good air hammers will have good touch control triggers that let users hit the material with just the right number of taps that it needs.

Rotary Hammer Price

Rotary hammers are some of the priciest tools you can invest in, and you can expect even the cheapest of entry-level rotary hammers to cost no less than 60 dollars. On the high end, SDS Max rotary hammers can easily run to 300 dollars or more.

Air Hammer Price

Air hammers with plastic parts are relatively cheaper, with basic models costing just 45 dollars or so. The best ones, made of heavy-duty alloy or aluminum bodies, can run up to 280 dollars, and that’s without the air compressor or the bits.