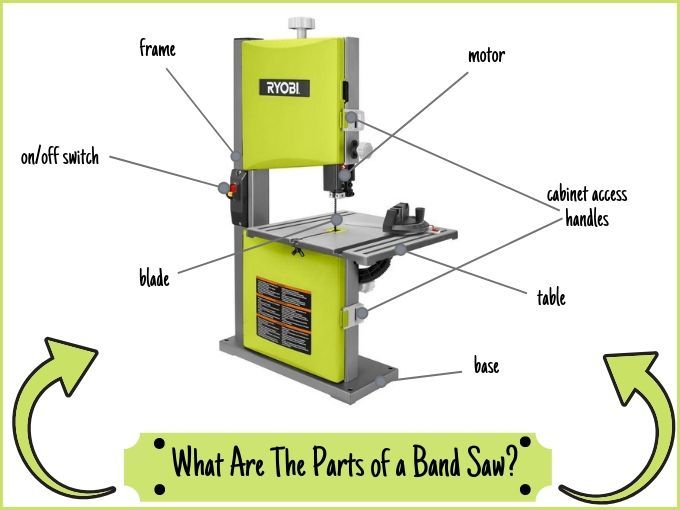

There are different bandsaws out there, and they are all a little different, but there are certain parts of a bandsaw that are essential, and knowing what and where they are is crucial.

I made this post on a Ryobi bandsaw because it is a much simpler model and easier to explain the features and parts, but it is important to note that there are many other models out there that have a little more functionality to them, and more settings, in most cases.

I wanted to keep it simple, though, and decided to use a smaller and simpler Ryobi bandsaw. I hope it helps!

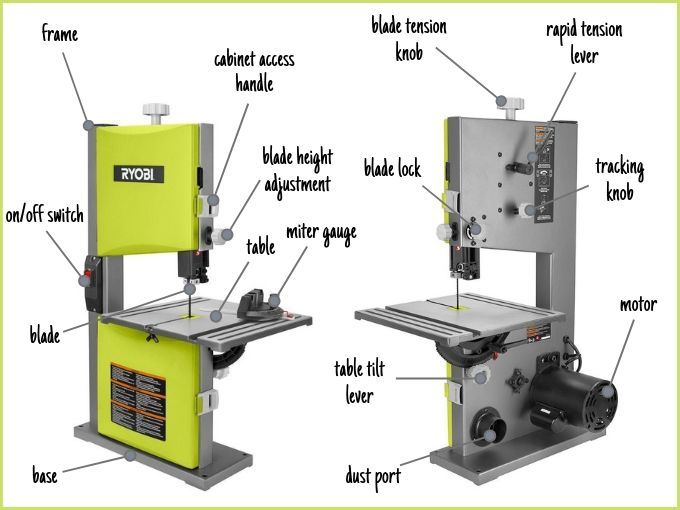

1. Frame

A bandsaw frame is the largest part or the tool itself where all of the other components are attached. Pulleys, motors, blades, and all other parts join on the frame to make up the whole bandsaw system. Basically, it’s just a part that supports all of the other smaller parts.

There are frames that are made of plastic and rugged steel or aluminum. Occasionally you may come across a bandsaw with a wooden frame. DIY bandsaw frames are wooden in most cases, and probably not the best choice, but will work for hobby type projects.

Bandsaws with plastic frames are generally cheaper, lighter, and easily portable. This is what you should go for in case you’re aiming at saving a few dollars. Otherwise, frames made of rugged steel are strong and stable.

2. Motor

This part pretty much runs the blades. It provides power to the cutting blades, depending on how strong it is. For wood cutting functions, a motor of above 2.5 amps power is sufficient. However, it’s a good idea to purchase a bandsaw with a larger motor that can handle harder materials. This would guarantee the saw can cut through a wider variety of materials.

Before you purchase a bandsaw, make sure you check its motor power. This is the backbone of the machine; the bandsaw won’t work if the motor fails, so it is worth putting the effort into the research process.

3. Pulleys

There are different pulleys performing specific functions on the bandsaw. For instance, a drive pulley is mounted on the motor, and its function is to move the drive belt, which controls the speed at which the blade cuts.

Pulley speed is measured in revolutions per minute (RPM). The speed at which the pulley rotates determines the strength of the cut.

There are two types of pulleys that play a vital role in the bandsaw's functionality.

A vector drive pulley has the ability to run the blades at a very high speed and the speed usually accelerates during the cutting process. A standard variable drive pulley allows the user to adjust speed without necessarily changing belts and sheaves.

4. Blade

A bandsaw blade is basically a long, thin strip metal with a serrated edge for cutting through wood and other materials, including metal. The strength of the blade and the teeth determines the type of material it can cut.

There are several factors to consider before choosing a blade. These include blade thickness, number of teeth, and style or design of teeth but there are also general cutting blades that will perform cuts on a wider array of materials.

A thick blade can handle tougher cutting jobs when compared to a thinner one. Blade thickness also depends on the diameter of bandsaw wheels and the track in which the blade fits in. In general, the more the number of teeth per inch the blade has, the smoother the blade will cut the material and the better the end result will be.

5. Table

This is the worktop of the bandsaw, where all of the magic will take place! It is located at the middle of the bandsaw and can come in many different widths and lengths. The throat capacity determines the size of material that can be cut by the bandsaw and is measured from the blade to the back of the table, where the frame meets the table.

The throat capacity is a very important metric When shopping around four different band saws because it essentially correlates to the size of the band saw itself and will be the major determining factor in how large of a workpiece you can use with the machine.

Most of the time, band saws will come with a table that is tiltable, one way or both ways depending on the model you get. The table can be made from many different materials such as steel, aluminum and sometimes even plastic on the smaller, more portable units.

6. Dust ports

Dust ports are pretty self-explanatory and seem to be more and more standard on various tools including band saws. The dust ports on various band saws will be a little bit different from manufacturer to manufacturer but they will still serve the same function, removing the material from the saw blade and out the port, into a vacuum of some sort.

Sucking out the dust can make the whole cutting process more efficient too. Directing the saw dust to a safe place where people will not be exposed to it is crucial.

7. Blade guides

These are the parts that essentially keep the bandsaw cutting blade in place, directing the cutting path. Setting the blade guides both above and below the table helps to keep the blade in place and also helps to reduce vibrations that may result from cutting. As with any tool, fewer vibrations guarantee a good quality cut.

The blade guide material greatly determines the rate of wear and tear, which is due to the friction that results when the blade is reciprocating. Carbide blade guides are a good choice because of their strength, but will still wear out with time, just like anything else.

You will also want to make sure you adjust your blade guide correctly (according to manufacturer specifications) in order to prevent excessive/premature wear.

8. Foot brake

What happens when you want to bring the whole cutting process to a stop? Or stop the wheels from rotating and the blade from cutting without switching the bandsaw off? Well, a foot brake does exactly that and works just like a brake in a car.

It is a mechanical brake whose efficiency depends on the amount of force you exert on it, so pushing it harder will make the bandsaw stop faster. The foot brake is suitable for emergencies and can also be used for convenience, if needed.

Foot brakes are usually only found on larger models that are free standing units and will not typically be found on benchtop models.

9. Rip fence

A rip fence serves the same purpose on a band saw that it does on a table saw and that is to make a suitable guide that you can use to slide your material along, in order to achieve a straight cut.

If you want a rip fence for your band saw then your two options are usually to either buy one from a third-party manufacturer or from the band saw’s manufacturer that will fit that specific model or to just make one yourself out of wood.

10. Magnetic switch

The magnetic switch is basically another name for the on/off button, which is self explanatory and turns the machine on and off.

There are different switches out there that have a different design to them, making them more convenient to use compared to other designs but really not that big of a deciding factor when looking at different band saws.