For a dedicated wood craftsman, a project may involve something as specific as woodturning – the process of shaping and carving wood as it is turned at high speed.

This process is as in-depth as you can get into woodworking, and often, it’s the only way to produce round wooden objects like bowls, table legs, bed posts, stair rail spindles and more. To do woodturning, you will definitely need a wood lathe, along with a good set of lathe tools to go with it.

How to Choose The Best Type of Wood Lathe?

A good wood lathe is the foundation of any woodturning project, and like with most power tools, the search for the best wood lathe for you starts by asking yourself a few important questions.

Type Of Projects: The first is, what sort of projects do you plan to do on your new lathe? Will they be small items like bowls or pens, or things as long as leg tables or staircase spindles?

Available Space: Then consider your workshop. Do you have a corner with enough space to place a full-size lathe with legs and the funds to do so? Or would you rather save space and invest in a benchtop wood lathe that you can bring out and use and put back if your work space is more limited.

Cost: Finally, there’s the question of price. Wood lathes, especially those made by the more well-known manufacturers, can run in the hundreds of dollars. Consider how much you can spend on a new lathe and if it is worth it.

Wood lathes are relatively simple machines, and a good one will last you for years or even decades.

If it is something that you will be using for projects that you plan to sell, or if you can see yourself doing woodturning as a long-term hobby, then you should consider investing into a wood lathe and lathe tools that will last longer and hold up to regular use.

Know the Parts of a Wood Lathe

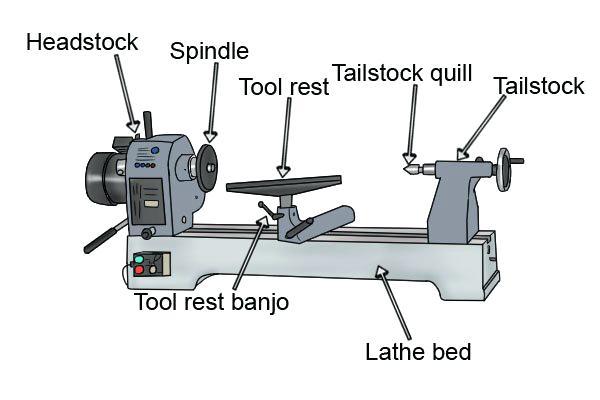

Woodturning has a set of terminology of its own, and for the purpose of buying a wood lathe, knowing the parts will at least let you compare the features of the unit that you plan to buy.

The picture below shows a benchtop model, which is smaller and does not have legs like a larger, stand alone model would.

ryumsh.info

The Wood Lathe Stand

The wood lathe stand is the frame that anchors everything together. Good wood lathe stands are usually made of heavy, solid cast iron, for the purpose of eliminating any vibrations and added stability as well as durability.

They can also be made (usually out of wood) for smaller models that will also double as an organizational tool for storing all of your lathe tool sets.

Parts of the Wood Lathe Stand

The Bed, often made of polished solid stainless steel, is where the other movable parts of the wood lathe are mounted on such that they can be slid forward or backward.

The Stand / Legs form the rest of the frame of the wood lathe. These can have legs in the standing wood lathe models, or they could be simply a platform that raises the tool on the bench for the benchtop models.

For standing models, you want a solid stand made of cast iron where the legs stick out the lower they go, for added stability.

If the stand comes with two or more sets of braces, the better – for lathes, any instability or vibration will ruin the job, aside from making the use of the tool dangerous to the user.

The Wood Lathe Headstock Explained...

The headstock forms one end of the wood lathe that holds the workpiece in place.

With wood lathes, the headstock is also usually the side that carries the motor, switch, and any readouts that the wood lathe may come with.

Usually, the headstock will be on the left side of the tool rest as it faces the user.

In most wood lathe models, the headstock will also be the piece on the bed that is fixed in place.

There are models, though, that come with a sliding headstock that can be adjusted along the bed – some of the more expensive ones even come with a headstock that can be pivoted around, which can be useful for shaping bowls and pieces that are simply too wide for the bed swing.

Using a pivoted headstock to shape a workpiece away from the bed is called outboard turning.

Parts of the Wood Lathe Headstock:

- The Motor and Switch are the main moving parts of the wood lathe, and they form the bulk of the headstock. If the wood lathe comes with variable speed controls and a readout for the current RPM, this is where they would be located as well.

If the wood lathe comes with a pulley and belt tension system, this is the part where it will be located – the same goes for any forward to reverse controls on the tool. - The Spindle holds one end of the workpiece as it turns it around. Most manufacturers will have their "specific" attachment system but always look for a lathe that can also take standard Morse tapers in both headstock and tailstock – a must for using universal centers and other aftermarket tooling options.

- The Headstock Lock, for units with sliding headstock, locks or unlocks it in place. Make sure to have this set in the lock position before operating the machine.

The Wood Lathe Tool Rest

The wood lathe tool rest is an adjustable short guide that slides along the bed and provides a place to hold your lathe shaping stool steady as the rotation of the workpiece pushes the tool downwards.

They are designed to slide along the bed to give your tool access to any part of the workpiece.

They can also be rotated so you have access to the bottom of bowls, as well. Make sure the wood lathe is at a standstill before making adjustments to the tool rest.

The tool rest should be easily adjusted then locked securely in place and should be immovable once locked. Good brands will also allow you to switch between short and long rests as needed.

The Wood Lathe Tailstock

The wood lathe tailstock is the opposite end from the headstock that holds the piece together.

In many wood lathe models, it is the tailstock that slides along the bed to pin the workpiece against the fixed headstock.

Parts of the Wood Lathe Tailstock:

- The Poppet Barrel holds the workpiece securely in tandem with the powered spindle on the headstock.

- The Handwheel and the Barrel Lock tightens the poppet barrel against the workpiece and the headstock, ensuring a fit that will not slip.

- The Tailstock itself often comes with small storage compartments for adjusting tools.

The tailstock lock secures the component against the bed – make sure this is on the lock position with the workpiece tightly clamped in place before starting the machine.

The Wood Lathe Tool Set

While the machine itself provides the platform, it’s the lathe toolset that ultimately shapes the material. The best tool sets are durable, sharp, and comes with good handles that can be gripped for hours without slipping.

Like most tool blades, wood lathe tool sets come in the easily sharpened High-Speed Steel (HSS) or the more durable Carbide blades.

The Standard Wood Lathe Tool Set:

Roughing Gouge

Spindle Gouge

Bowl Gouge

Skew Chisel

Parting Tool

Round Nose Scraper

Choosing the Wood Lathe Base: Size Matters

Choosing the right wood lathe for your shop starts with the bed of the lathe, or the main horizontal beam that will hold your workpiece as it is being turned.

The bed is a heavy-duty component of the wood lathe and is usually made from cast iron.

Depending on the project you want to do on your lathe as well as the space available in your workshop, you should consider investing in one big enough and long enough to hold the longest work pieces you will be turning.

The Mini Lathe

If you are planning to turn small household items or decorative pieces, then the mini wood lathe might be right for you.

They are the smallest wood lathe that you can buy, and they come with the most light-weight of engines, as well.

The typical mini lathe will have an engine of about 1 horsepower (HP), with just the right power to safely turn small wood projects around as you work on them.

sears.com

A mini lathe will have a space of less than 18 inches from center to center, which means your work pieces will have to fit in less than one and a half feet of bed space. These smaller models would also have less than 12 inches of clearance above the bed as well.

Almost all mini lathes on the market are the benchtop type, which means you can keep these ones stored away on a shelf when not in use.

The Midi Lathe

The midi wood lathe is bigger in every way than the mini lathe, and you will start to see stand-alone units with their own legs. While some midi lathes still use the traditional pulley and belt speed regulation system, many of the newer models today now offer electronic variable speed setting.

Midi lathes cover projects a mini lathe can do and really bridges "the gap" between a smaller lathe and a larger one.

The Full-Sized Lathe

This is the lathe that occupies a corner of your workshop, with almost all models being the stand-alone type with their own legs.

For longer pieces like table legs, there’s really no substitute for a full-sized wood lathe.

purplewave.com

The space between the centers of a typical full-size wood lathe would measure 40 inches or more, with the swing distance, or clearance over the bed, measuring over 15 inches.

Comparing Wood Lathes

The wood lathe is one of the oldest and well-established power tools you can find, and generally, the woodturning community has often settled on certain makes from certain brands as recommendations.

Ideally, you have figured out the size of the wood lathe you want for your project – between mini, midi, and full-sized lathe, most of the difference aside from size comes down to build quality and capacity.

Wood Lathe Weight

Unlike most power tools, you want a hefty wood lathe – the heavier the better. Most of the better wood lathe brands are made of solid cast iron, and for good reason: the workpiece will often spin unbalanced at the start of the job, and it will be up to the spindle, bed and wood lathe stand to withstand the vibrations to maintain a smooth rotation.

A substantial weight also suggests good build quality, a prime consideration in choosing a machine like this. A nice heavy wood lathe from a good manufacturer will run quieter, more smoothly, and will last longer to give you perfect turning results.

Wood Lathe Motor and Drive

With wood turning, more torque and power is always welcome. Even with mini wood lathes, find a unit with at least 1/3 HP.

In wood lathes, there are appropriate rotation speeds for certain jobs, and faster does not necessarily mean better. In practice, most wood lathes will have a range of speeds from 400 rotations per minute (400 RPM) for slower, more delicate work to 2000 RPM for rough cutting or grinding.

Traditional wood lathe drives are fitted with three or four pulleys to give a range of speeds. Pulley systems, while effective, can be fussy when it comes to speed switching – plus there is the matter of replacing belts when they eventually wear out.

Electronic speed control, on the other hand, gives you the ability to turn the speed up or down with the click of the dial. Older electric speed control models used to have issues with lower torque at low speeds, but modern inverter technology has all but eliminated this problem with the newer models.

Wood Lathe Safety Tips

Like with most power tools, a wood lathe should be used with safety in mind, always approach the spinning workpiece deliberately with the proper tools.

Never, under any circumstances, place your hand, fingers, or anything other than a woodturning tool near a rapidly rotating stock or the tool rest, and always wear eye protection when working with a wood lathe. Remove any loose clothing, jeweley or anything else that could get sucked in by the lathe.

Follow the owner’s manual and the safety requirements described in it. Always follow the maintenance guidelines – a well-maintained wood lathe is a tool that’s safer and more fun to use.