Most compressors nowadays that are more "value" priced tend to be quite loud and making them quieter seems to be a viable solution...

Right?

I wanted to see if I could find a few "hacks" that would suppress the noise produced by one of these compressors and if they existed, how well they worked.

I found a ton of different articles and videos online that resulted in many more hours than I (originally) anticipated putting into this article but I learned a lot and am glad it took as long as it did. Here's what I found...

How Do You Make An Air Compressor Quiet?

If you don't end up buying a quiet air pressure than you can reduce the amount of sound your existing compressor puts out by modifying the parts or building a soundproof room around it.

This is the short answer, of course and we will dive a little bit deeper into some of these later on in this article but that is basically what my research concluded.

What Causes A Noisy Air Compressor Anyways?

There are a number of things that can cause a compressor to be noisy and some are related to vibrations and others are related more towards the parts of the compressor.

You can use a decibel meter (found at Amazon) to measure the amount of decibels that your compressor currently pumps out, modify it and test the results again.

Some of the more common factors I found are:

- Intake: This is the most common problem and is where the majorit of the noise tends to come from but is one of the easiest things to fix, with a little ingenuity.

- Exhaust: The exhaust is one of the other "major" contributors to a compressor's LOUDNESS and is more geared towards a unit that has a gasoline engine mounted on it.

- Vibrational Noise: Vibrational noises don't necessarily account for the bulk majority of the noise but will have its own annoying (often repetitive) beat to it, making it noticeable.

- Type Of Materials Used: The types of metals that the manufacturer uses will actually make the compressor have a different sound to it and the cheaper types of compressors made with a lesser grade metal will tend to have a different tone than one made from a more superior metal.

- What Type Of Compressor You Have: There will be a difference in tone on a direct drive compressor and a belt-driven model. They can operate at around the same decibel level but the sound will generally be different.

Let's Look At The Average Compressor...

I think that in order to make a post on how to effectively quiet noisy air compressor or to get a quiet air press or even quieter it would make sense to take a look at some of the other compressors out there to see what kind of noise (in decibels) they produce.

We can figure out if what we're doing is working and can actually measure the result by figuring out the difference in the the number of decibels the the compressor puts out before and after I make any modifications.

The average compressor seems to put out around 70 to 90 dB but I would have to say that the majority of them came in and around 80 dB, or so. Some of the silent models (California Air Tools Brand compressors) did tackle the noise problem and some of them ran around 60 dB, which is much quieter than the average but still not as quiet as some specialty compressors I have seen, which is around 40 to 50 dB.

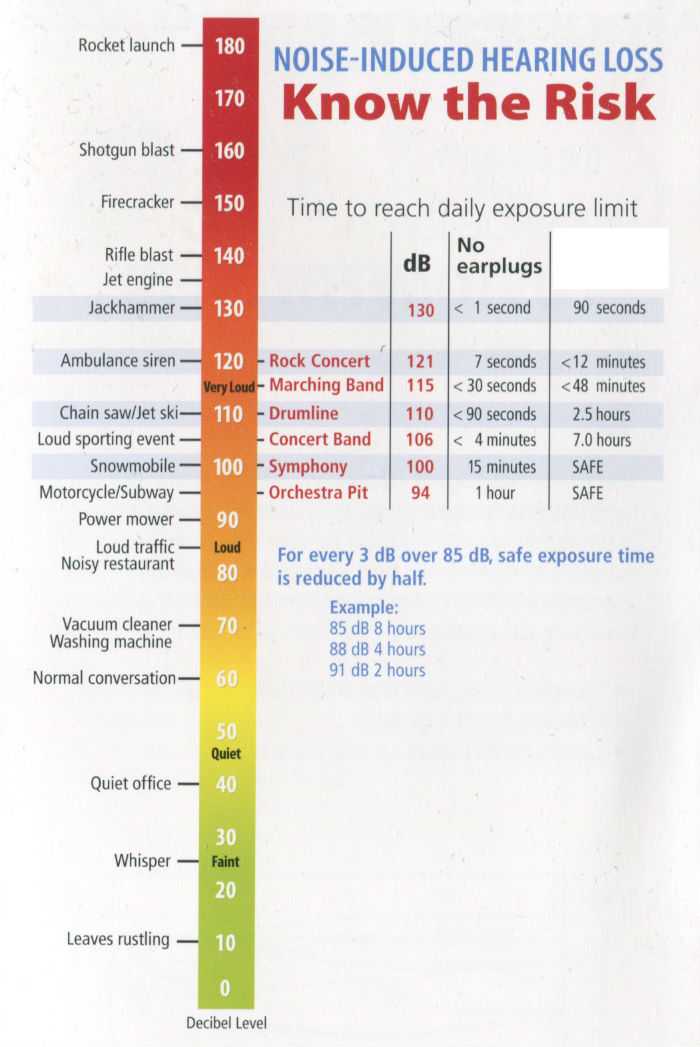

I wanted to include the (below) decibel chart in this post that I found from creativefieldreporting.com to give you an idea of how many decibels common items operate at, to give you better idea of what to expect and to get you familiar with the scale of sound.

creativefieldrecording.com

A Neat Comparison I Found Online...

In the research process in making this article I stumbled on a video that compares three different compressors, a direct drive compressor, a belt driven compressor and a smaller portable compressor that is specifically made to be nearly half as loud as the other two compressors and it was mind blowing!

This was just a basic test and the to allow outer air compressors were a lot more powerful than a third model but ran at around 73 dB to 74 dB and were quite loud but was pretty accurate as far as the majority of the air compressors out there and the decibel levels that they operate at.

The quiet compressor ran at around 40 dB and that kind of difference is SIGNIFICANT and really gives you an idea of what kind of technologies out there and how much sound you can actually suppress from an air compressor and I thought it was just a really good example of an overall comparison that I think a lot of people would find helpful as well.

The video is no longer available on youtube :(.

Let's Look At Some Specialty Compressor That Are Made To Be Quiet...

I wanted to look at some air compressors that are made specifically for their MUCH LOWER noise producing properties, to get a better overall idea of what they are doing to suppress the noise and to see if there's anything I can replicate myself.

silentaire.com

dentallabservices.com

The majority of the higher end compressors that were specifically designed to produce around 40 dB of noise all had in encapsulated motor like the image on the right shows.

This really seem to be the main distinction in sound levels from all of the other compressors out there but these were very expensive too, costing upwards of $800 in price and probably not appealing to most people because of that.

I'm not sure what they're using in the capsule itself, whether it's a high density foam or something to that effect but 40 dB is hard to ignore and is half the sound output of other more common air compressors suit is worth taking a look at.

What Others Are Doing To Suppress Sound:

I spend a little time looking at various YouTube videos, forums and blogs to gather some of the things that people are doing to get their compressors quieter.

These are mainly DIY type hacks and some work better than others but I think it'll be a helpful list for those of you out there that want to try to suppress some of that noise on your own without spending a fortune on a specialty type of air compressor.

Note: These our examples I found online and anything you try to do on your own is at your own risk, so be aware that I am simply providing a resource for educational purposes, nothing more.

- Connecting Muffler To Intake: I found a video online where a man took heavy duty air hoses and connected them to the intake of his compressor and attached the other end to a muffler.

He reported a difference of 4 dB difference and he shows an example of the hack with the hoses connected and disconnect and it seemed to make a significant difference in the amount of sound the compressor put out (in my opinion). - Installing Rubber Grommets To Motor: I found another video online (youtube video) where a guy installs rubber grommets on the motor itself so it acts as a dampener between the motor mounting bracket of the oppressor and the compressor frame itself which I believe would eliminate a lot of vibrational noise caused by compressors.

He didn't specifically state that it was for a compressor motor but I think the idea is a valid one that would work and is worth experimenting with because I know the rubber grommets would help eliminate a lot of the vibration that the motor causes and would likely result in some kind of noise suppression. - Extending The Intake And Mounting It Outdoors: The next example I stumbled on was another video on extending the intake of the compressor and running that on the exterior of the building. This was probably one of the easier hacks I found and would require very minimal materials and be pretty simple to do.

He gives an example of the compressor running before he did this and after but there only seem to be a slight difference in the amount of noise, from what I gathered anyways please watch the video yourself and let me know what you think in the comments below. - Encapsulating The Compress: This was the most common suggest made by many people (especially in forums) and is probably the most expensive option as well because it requires a lot of building materials and if you don't own any power tools and you will need some of the basics like a circular saw, drill, etc.

By encapsulating, I mean to actually build a room around the compressor itself that has some sort of sound deadening material within the wall, like a sound deadening (acoustic) foam panel (which you can find at Amazon) or some other foam insulation board to help eliminate a lot of the sound.

Just be sure that you have proper ventilation to that area or your compressor will run the risk of overheating and dying on you. Running the intake outdoors will also help out a lot in an enclosed area. - Wrapping The Compressor: I did find a couple of suggestions that were stated by a couple of people (in online forums) that stated if you wrap the compressor with something, like you would a hot water heater, then it would help suppress some of the noise.

The suggestions were carpet (low budget?) and a sound deadening mat of some sort, like these found on Amazon. I wasn't sure what part of the compressor they would be wrapping but I assume it was the motor area and not the tank (wouldn't make sense to do that). If I find any more information, I will update it asap.

Did I leave anything out or is there something you would like to suggest? Leave me a comment (below) and I will gladly check into it and list it, as I am going to be constantly updating this article.